Page 557 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 557

,§;!i§§*¥* §¢

Q

powder

, get-3d.§§e2§Z@», 537

ii-eg; e~.;,,;';.¥;a1;

Additive Processes

Section 20.3

infiltrating metal, permeates into P/M

Binder deposition

Bidder

‘

\

\\

li/licrostructure detail is

Metal

powder ¥s#;4¥éE;dEd§='

*seed artist’

Particles are loosely sintered; infiltrated by

Binder is burned off lower-melting-point metal

(21) (bl (C)

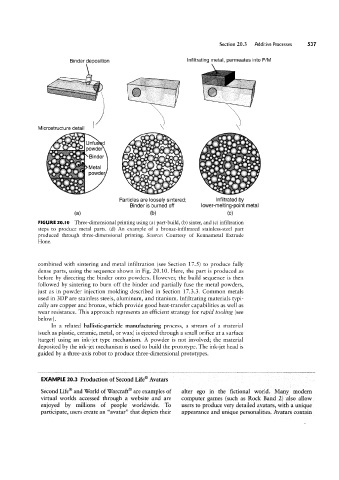

FIGURE 20.|0 Three-dimensional printing using (a) part-build, (b) sinter, and (c) infiltration

steps to produce metal parts. (d) An example of a bronze-infiltrated stainless-steel part

produced through three-dimensional printing. Source: Courtesy of Kennametal Extrude

Hone.

combined with sintering and metal infiltration (see Section 17.5 ) to produce fully

dense parts, using the sequence shown in Fig. 20.10. Here, the part is produced as

before by directing the binder onto powders. However, the build sequence is then

followed by sintering to burn off the binder and partially fuse the metal powders,

just as in powder injection molding described in Section 17.33. Common metals

used in SDP are stainless steels, aluminum, and titanium. Infiltrating materials typi-

cally are copper and bronze, which provide good heat-transfer capabilities as well as

wear resistance. This approach represents an efficient strategy for rapid tooling (see

below).

In a related ballistic-particle manufacturing process, a stream of a material

(such as plastic, ceramic, metal, or wax) is ejected through a small orifice at a surface

(target) using an ink-jet type mechanism. A powder is not involved; the material

deposited by the ink-jet mechanism is used to build the prototype. The ink-jet head is

guided by a three-axis robot to produce three-dimensional prototypes.

EXAMPLE 20.3 Production of Second Life® Avatars

Second Life® and World of Warcraft® are examples of alter ego in the fictional world. Many modern

virtual worlds accessed through a website and are computer games (such as Rock Band 2) also allow

enjoyed by millions of people worldwide. To users to produce very detailed avatars, with a unique

participate, users create an “avatar” that depicts their appearance and unique personalities. Avatars contain