Page 553 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 553

Section 20.3 Additive Processes 533

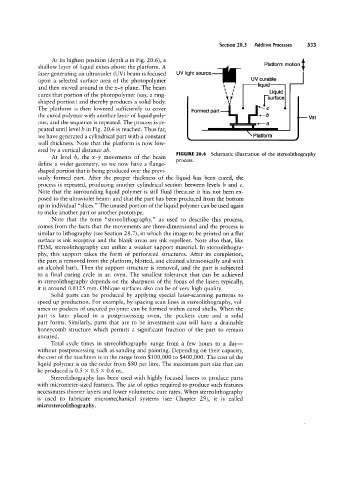

At its highest position (depth a in Fig. 20.6), a

Platform motion

shallow layer of liquid exists above the platform. A

laser generating an ultraviolet (UV) beam is focused UV light source

upon a selected surface area of the photopolymer UV curable

liquid

and then moved around in the x-y plane. The beam \ I’

Liquid

cures that portion of the photopolymer (say, a ring- x ; surface

shaped portion) and thereby produces a solid body. V

The platform is then lowered sufficiently to cover 3 c

Formed part

the cured polymer with another layer of liquid poly- "b Vat

mer, and the sequence is repeated. The process is re- | |

peated until level b in Fig. 20.6 is reached. Thus far,

we have generated a cylindrical part with a constant Platform

wall thickness. Note that the platform is now low-

ered by a vertical distance ab.

FIGURE 20.6 Schematic illustration of the stereolithography

At level b, the x-y movements of the beam

process.

define a wider geometry, so we now have a flange-

shaped portion that is being produced over the previ-

ously formed part. After the proper thickness of the liquid has been cured, the

process is repeated, producing another cylindrical section between levels I9 and c.

Note that the surrounding liquid polymer is still fluid (because it has not been ex-

posed to the ultraviolet beam) and that the part has been produced from the bottom

up in individual “slices.” The unused portion of the liquid polymer can be used again

to make another part or another prototype.

Note that the term “stereolithography,” as used to describe this process,

comes from the facts that the movements are three-dimensional and the process is

similar to lithography (see Section 28.7), in which the image to be printed on a flat

surface is ink receptive and the blank areas are ink repellent. Note also that, like

FDM, stereolithography can utilize a weaker support material. In stereolithogra-

phy, this support takes the form of perforated structures. After its completion,

the part is removed from the platform, blotted, and cleaned ultrasonically and with

an alcohol bath. Then the support structure is removed, and the part is subjected

to a final curing cycle in an oven. The smallest tolerance that can be achieved

in stereolithography depends on the sharpness of the focus of the laser; typically,

it is around 0.0125 mm. Oblique surfaces also can be of very high quality.

Solid parts can be produced by applying special laser-scanning patterns to

speed up production. For example, by spacing scan lines in stereolithography, vol-

umes or pockets of uncured polymer can be formed within cured shells. When the

part is later placed in a postprocessing oven, the pockets cure and a solid

part forms. Similarly, parts that are to be investment cast will have a drainable

honeycomb structure which permits a significant fraction of the part to remain

uncured.

Total cycle times in stereolithography range from a few hours to a day-

without postprocessing such as sanding and painting. Depending on their capacity,

the cost of the machines is in the range from $100,000 to $400,000. The cost ofthe

liquid polymer is on the order from $80 per litre. The maximum part size that can

be produced is 0.5 >< 0.5 >< 0.6 m..

Stereolithography has been used with highly focused lasers to produce parts

with micrometer-sized features. The use of optics required to produce such features

necessitates thinner layers and lower volumetric cure rates. When stereolithography

is used to fabricate micromechanical systems (see Chapter 29), it is called

microstereolithography.