Page 551 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 551

Section 20.3 Additive Processes

é

fi

Side View

(H) (D)

'/2:

Model Model

yii Su ort \ \

'Q pp

Z ,&» ea /2

,~%v §§§!fé”' /‘

/

A Support

(C) (Cl)

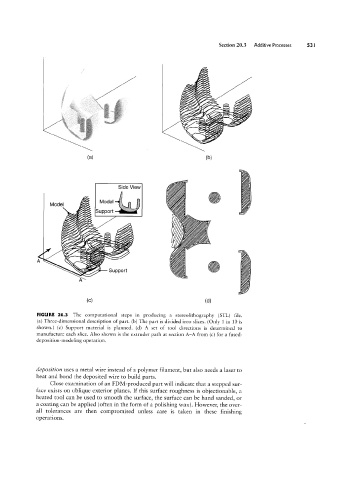

FIGURE 20.3 The computational steps in producing a stereolithography (STL) file.

(a) Three-dimensional description of part. (b) The part is divided into slices. (Only 1 in 10 is

shown.) (c) Support material is l p anne d. (d) A set of tool directions is determined to

manufacture each slice. Also shown is the extruder path at section A-A from (c) for a fused-

deposition-modeling operation.

deposition uses a metal Wire instead of a polymer filament, but also needs a laser to

heat and bond the deposited Wire to build parts.

Close examination of an FDM-produced part will indicate that a stepped sur-

face exists on oblique exterior planes. If this surface roughness is objectionable, a

heated tool can be used to smooth the surface, the surface can be hand sanded, or

a coating can be applied (often in the form of a polis h'mg Wax ). However, the over-

all tolerances are then compromise d unless care is taken in these finishing

operations.