Page 555 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 555

Section 20.3 Addntive Processes

Galvanometers gp

§`

Sintering laser

I

I

Optics

Laser

E

Environmental-

COHUOI Unit

Process-control + *

'

computer C -W

'n~~

I

Wh

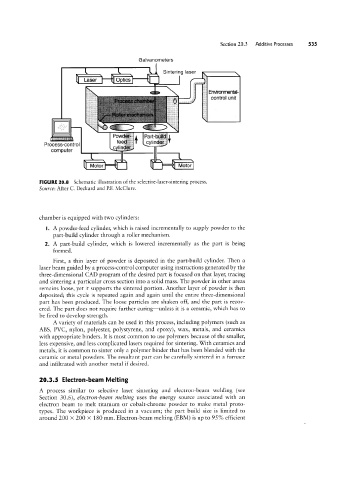

FIGURE 20.8 Schematic illustration of the selective-laser-sintering process.

Source: After C. Deckard and P.F. McClure.

chamber is equipped with two cylinders:

I. A powder-feed cylinder, which is raised incrementally to supply powder to the

part-build cylinder through a roller mechanism.

2. A part-build cylinder, which is lowered incrementally as the part is being

formed.

First, a thin layer of powder is deposited in the part-build cylinder. Then a

laser beam guided by a process-control computer using instructions generated by the

three-dimensional CAD program of the desired part is focused on that layer, tracing

and sintering a particular cross section into a solid mass. The powder in other areas

remains loose, yet it supports the sintered portion. Another layer of powder is then

deposited; this cycle is repeated again and again until the entire three-dimensional

part has been produced. The loose particles are shaken off, and the part is recov-

ered. The part does not require further curing-unless it is a ceramic, which has to

be fired to develop strength.

A variety of materials can be used in this process, including polymers (such as

ABS, PVC, nylon, polyester, polystyrene, and epoxy), wax, metals, and ceramics

with appropriate binders. It is most common to use polymers because of the smaller,

less expensive, and less complicated lasers required for sintering. With ceramics and

metals, it is common to sinter only a polymer binder that has been blended with the

ceramic or metal powders. The resultant part can be carefully sintered in a furnace

and infiltrated with another metal if desired.

20.3.5 Electron-beam Melting

A process similar to selective laser sintering and electron-beam welding (see

Section 30,6), electron-beam melting uses the energy source associated with an

electron beam to melt titanium or cobalt-chrome powder to make metal proto-

types. The workpiece is produced in a vacuum; the part build size is limited to

around 200 >< 200 >< 180 mm. Electron-beam melting (EBM) is up to 95% efficient