Page 552 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 552

32 Chapter 20 Rapid-Prototyping Processes and Operations

Thermoplastic

filament

z

,V

X

Heated build head gi Efggfgdffde'

moves in x-y plane minutes

Filament supply 2

--~___f~e;»

Table "-.,,_A_ V'

moves in

z-direction Fixtureless

(H) (D)

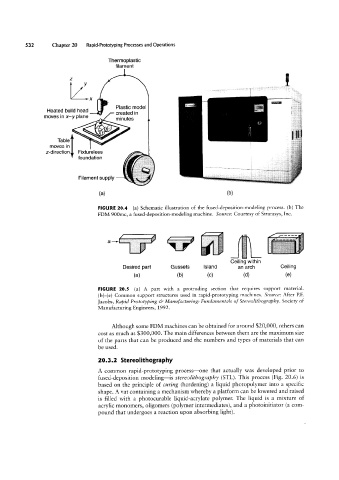

FIGURE 20.4 (a) Schematic illustration of the fused-deposition-modeling process. (b) The

FDM 900mc, a fused-deposition-modeling machine. Source: Courtesy of Stratasys, Inc.

Ceiling within

Desired part Gussets Island an arch Ceiling

(H) (D) (C) (Ol) (G)

FIGURE 20.5 (a) A part with a protruding section that requires support material.

(b)-(e) Common support structures used in rapid-prototyping machines. Source: After P.F.

Jacobs, Rapid Prototyping ca” Manufacturing: Fundamentals of Stereolithography. Society of

Manufacturing Engineers, 1992.

Although some FDM machines can be obtained for around $20,000, others can

cost as much as $300,000. The main differences between them are the maximum size

of the parts that can be produced and the numbers and types of materials that can

be used.

20.3.2 Stereolithography

A common rapid-prototyping process-one that actually was developed prior to

fused-deposition modeling-is stereolit/aography (STL). This process (Fig. 20.6) is

based on the principle of curing (hardening) a liquid photopolymer into a specific

shape. A vat containing a mechanism whereby a platform can be lowered and raised

is filled with a photocurable liquid-acrylate polymer. The liquid is a mixture of

acrylic monomers, oligomers (polymer intermediates), and a photoinitiator (a com-

pound that undergoes a reaction upon absorbing light).