Page 577 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 577

Chapter 21 Fundamentals of Machining

Rough Surface Shiny surface

Rake face

Chlp Tool

Shea' Rake angle

Flank face

Relief or

clearance

angle

Shear angle

(H)

I

Rough surface

Rake face

1 Tool

Primary Hake angle

shear zone

Flank face

Rough

surface

(D)

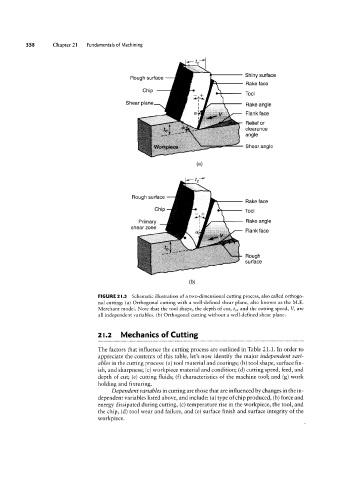

FIGURE 2I.3 Schematic illustration of a two-dimensional cutting process, also called orthogo-

nal cutting: (a) Orthogonal cutting with a well-defined shear plane, also known as the M.E.

Merchant model. Note that the tool shape, the depth of cut, to, and the cutting speed, V, are

all independent variables. (b) Orthogonal cutting without a well-defined shear plane.

2|.2 Mechanics of Cutting

The factors that influence the cutting process are outlined in Table 21.1. In order to

appreciate the contents of this table, let’s now identify the major independent vari-

ables in the cutting process: (a) tool material and coatings; (b) tool shape, surface fin-

ish, and sharpness; (C) workpiece material and condition; (d) cutting speed, feed, and

depth of cut; (e) cutting fluids; (f) characteristics of the machine tool; and (g) work

holding and fixturing.

Dependent variables in cutting are those that are influenced by changes in the in-

dependent variables listed above, and include: (a) type of chip produced, (b) force and

energy dissipated during cutting, (c) temperature rise in the workpiece, the tool, and

the chip, (d) tool wear and failure, and (e) surface finish and surface integrity of the

workpiece.