Page 409 - Marine Structural Design

P. 409

Chapter 20 Spectral Fatigue Analysis and Design 385

In addition to the weld toe, which is the most usual site for fatigue cracking to occur, all load

carrying fillet welds and partial penetration butt welds must be evaluated to assess possible

weld throat failure. To avoid this type of failure, it is necessary to ensure that these joints are

adequately dimensioned. This may be achieved using the Class W design S-N curve. One

should note that the maximum shear stress range is associated with the class W design S-N

curve.

Structural Details

The UK DEn fatigue design and assessment guidelines provide sketches, which provide

assistance in the S-N classification of structural details. According to UK DEn (1990)

guidelines, joints are subdivided into the following types:

Metal free from welding

Continuous welds essentially parallel to the direction of applied stress

Transverse butt welds

Weld attachments on the surface of a stressed member

Load-carrying fillet and T butt welds

Details in welded girders

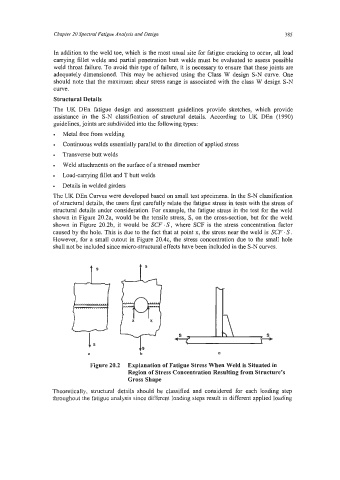

The UK DEn Curves were developed based on small test specimens. In the S-N classification

of structural details, the users first carefully relate the fatigue stress in tests with the stress of

structural details under consideration. For example, the fatigue stress in the test for the weld

shown in Figure 20.2a, would be the tensile stress, S, on the cross-section, but for the weld

shown in Figure 20.2b, it would be SCF S , where SCF is the stress concentration factor

caused by the hole. This is due to the fact that at point x, the stress near the weld is SCF S .

However, for a small cutout in Figure 20.4c, the stress concentration due to the small hole

shall not be included since micro-structural effects have been included in the S-N curves.

ts

C

Figure 20.2 Explanation of Fatigue Stress When Weld is Situated in

Region of Stress Concentration Resulting from Structure’s

Gross Shape

Theoretically, structural details should be classified and considered for each loading step

throughout the fatigue analysis since different loading steps result in different applied loading