Page 151 - Materials Science and Engineering An Introduction

P. 151

4.9 Basic Concepts of Microscopy • 123

Microscopic Examination

4.9 BASIC CONCEPTS OF MICROSCOPY

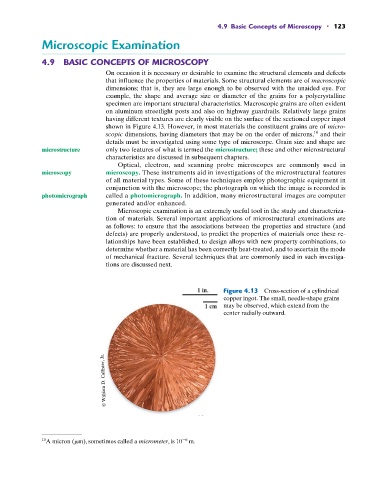

On occasion it is necessary or desirable to examine the structural elements and defects

that influence the properties of materials. Some structural elements are of macroscopic

dimensions; that is, they are large enough to be observed with the unaided eye. For

example, the shape and average size or diameter of the grains for a polycrystalline

specimen are important structural characteristics. Macroscopic grains are often evident

on aluminum streetlight posts and also on highway guardrails. Relatively large grains

having different textures are clearly visible on the surface of the sectioned copper ingot

shown in Figure 4.13. However, in most materials the constituent grains are of micro-

10

scopic dimensions, having diameters that may be on the order of microns, and their

details must be investigated using some type of microscope. Grain size and shape are

microstructure only two features of what is termed the microstructure; these and other microstructural

characteristics are discussed in subsequent chapters.

Optical, electron, and scanning probe microscopes are commonly used in

microscopy microscopy. These instruments aid in investigations of the microstructural features

of all material types. Some of these techniques employ photographic equipment in

conjunction with the microscope; the photograph on which the image is recorded is

photomicrograph called a photomicrograph. In addition, many microstructural images are computer

generated and/or enhanced.

Microscopic examination is an extremely useful tool in the study and characteriza-

tion of materials. Several important applications of microstructural examinations are

as follows: to ensure that the associations between the properties and structure (and

defects) are properly understood, to predict the properties of materials once these re-

lationships have been established, to design alloys with new property combinations, to

determine whether a material has been correctly heat-treated, and to ascertain the mode

of mechanical fracture. Several techniques that are commonly used in such investiga-

tions are discussed next.

Figure 4.13 Cross-section of a cylindrical

copper ingot. The small, needle-shape grains

may be observed, which extend from the

center radially outward.

© William D. Callister, Jr.

6

10 A micron ( m), sometimes called a micrometer, is 10 m.