Page 19 - Materials Science and Engineering An Introduction

P. 19

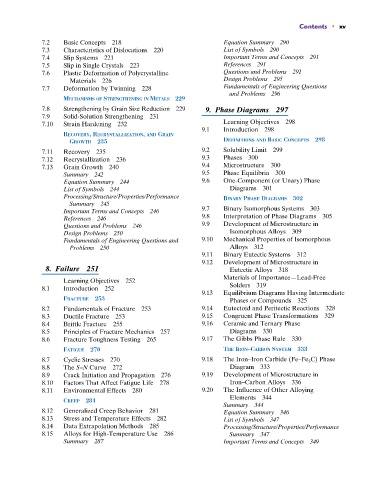

Contents • xv

7.2 Basic Concepts 218 Equation Summary 290

7.3 Characteristics of Dislocations 220 List of Symbols 290

7.4 Slip Systems 221 Important Terms and Concepts 291

7.5 Slip in Single Crystals 223 References 291

7.6 Plastic Deformation of Polycrystalline Questions and Problems 291

Materials 226 Design Problems 295

7.7 Deformation by Twinning 228 Fundamentals of Engineering Questions

and Problems 296

MECHANISMS OF STRENGTHENING IN METALS 229

7.8 Strengthening by Grain Size Reduction 229 9. Phase Diagrams 297

7.9 Solid-Solution Strengthening 231

7.10 Strain Hardening 232 Learning Objectives 298

9.1 Introduction 298

RECOVERY, RECRYSTALLIZATION, AND GRAIN

GROWTH 235 DEFINITIONS AND BASIC CONCEPTS 298

7.11 Recovery 235 9.2 Solubility Limit 299

7.12 Recrystallization 236 9.3 Phases 300

7.13 Grain Growth 240 9.4 Microstructure 300

Summary 242 9.5 Phase Equilibria 300

Equation Summary 244 9.6 One-Component (or Unary) Phase

List of Symbols 244 Diagrams 301

Processing/Structure/Properties/Performance BINARY PHASE DIAGRAMS 302

Summary 245 9.7 Binary Isomorphous Systems 303

Important Terms and Concepts 246

References 246 9.8 Interpretation of Phase Diagrams 305

Questions and Problems 246 9.9 Development of Microstructure in

Design Problems 250 Isomorphous Alloys 309

Fundamentals of Engineering Questions and 9.10 Mechanical Properties of Isomorphous

Problems 250 Alloys 312

9.11 Binary Eutectic Systems 312

9.12 Development of Microstructure in

8. Failure 251 Eutectic Alloys 318

Learning Objectives 252 Materials of Importance—Lead-Free

8.1 Introduction 252 Solders 319

9.13 Equilibrium Diagrams Having Intermediate

FRACTURE 253 Phases or Compounds 325

8.2 Fundamentals of Fracture 253 9.14 Eutectoid and Peritectic Reactions 328

8.3 Ductile Fracture 253 9.15 Congruent Phase Transformations 329

8.4 Brittle Fracture 255 9.16 Ceramic and Ternary Phase

8.5 Principles of Fracture Mechanics 257 Diagrams 330

8.6 Fracture Toughness Testing 265 9.17 The Gibbs Phase Rule 330

FATIGUE 270 THE IRON–CARBON SYSTEM 333

8.7 Cyclic Stresses 270 9.18 The Iron–Iron Carbide (Fe–Fe 3 C) Phase

8.8 The S–N Curve 272 Diagram 333

8.9 Crack Initiation and Propagation 276 9.19 Development of Microstructure in

8.10 Factors That Affect Fatigue Life 278 Iron–Carbon Alloys 336

8.11 Environmental Effects 280 9.20 The Influence of Other Alloying

Elements 344

CREEP 281

Summary 344

8.12 Generalized Creep Behavior 281 Equation Summary 346

8.13 Stress and Temperature Effects 282 List of Symbols 347

8.14 Data Extrapolation Methods 285 Processing/Structure/Properties/Performance

8.15 Alloys for High-Temperature Use 286 Summary 347

Summary 287 Important Terms and Concepts 349