Page 231 - Materials Science and Engineering An Introduction

P. 231

Summary • 203

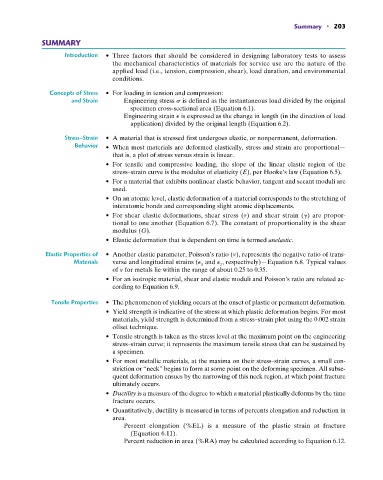

SUMMARY

Introduction • Three factors that should be considered in designing laboratory tests to assess

the mechanical characteristics of materials for service use are the nature of the

applied load (i.e., tension, compression, shear), load duration, and environmental

conditions.

Concepts of Stress • For loading in tension and compression:

and Strain Engineering stress s is defined as the instantaneous load divided by the original

specimen cross-sectional area (Equation 6.1).

Engineering strain P is expressed as the change in length (in the direction of load

application) divided by the original length (Equation 6.2).

Stress–Strain • A material that is stressed first undergoes elastic, or nonpermanent, deformation.

Behavior • When most materials are deformed elastically, stress and strain are proportional—

that is, a plot of stress versus strain is linear.

• For tensile and compressive loading, the slope of the linear elastic region of the

stress–strain curve is the modulus of elasticity (E), per Hooke’s law (Equation 6.5).

• For a material that exhibits nonlinear elastic behavior, tangent and secant moduli are

used.

• On an atomic level, elastic deformation of a material corresponds to the stretching of

interatomic bonds and corresponding slight atomic displacements.

• For shear elastic deformations, shear stress (t) and shear strain (g) are propor-

tional to one another (Equation 6.7). The constant of proportionality is the shear

modulus (G).

• Elastic deformation that is dependent on time is termed anelastic.

Elastic Properties of • Another elastic parameter, Poisson’s ratio (v), represents the negative ratio of trans-

Materials verse and longitudinal strains (P x and P z , respectively)—Equation 6.8. Typical values

of v for metals lie within the range of about 0.25 to 0.35.

• For an isotropic material, shear and elastic moduli and Poisson’s ratio are related ac-

cording to Equation 6.9.

Tensile Properties • The phenomenon of yielding occurs at the onset of plastic or permanent deformation.

• Yield strength is indicative of the stress at which plastic deformation begins. For most

materials, yield strength is determined from a stress–strain plot using the 0.002 strain

offset technique.

• Tensile strength is taken as the stress level at the maximum point on the engineering

stress–strain curve; it represents the maximum tensile stress that can be sustained by

a specimen.

• For most metallic materials, at the maxima on their stress–strain curves, a small con-

striction or “neck” begins to form at some point on the deforming specimen. All subse-

quent deformation ensues by the narrowing of this neck region, at which point fracture

ultimately occurs.

• Ductility is a measure of the degree to which a material plastically deforms by the time

fracture occurs.

• Quantitatively, ductility is measured in terms of percents elongation and reduction in

area.

Percent elongation (%EL) is a measure of the plastic strain at fracture

(Equation 6.11).

Percent reduction in area (%RA) may be calculated according to Equation 6.12.