Page 261 - Materials Science and Engineering An Introduction

P. 261

7.10 Strain Hardening • 233

140

120 900

800

1040 Steel

1040 Steel 120

800

700 100 700 100

600

Yield strength (MPa) 500 Brass 80 Yield strength (ksi) Tensile strength (MPa) 600 Brass 80 Tensile strength (ksi)

60

400

Copper 500

300 60

40 400

Copper

200

300

20 40

100

200

0 10 20 30 40 50 60 70 0 10 20 30 40 50 60 70

Percent cold work Percent cold work

(a) (b)

70

60

50

Ductility (%EL) 40 Brass

30

20

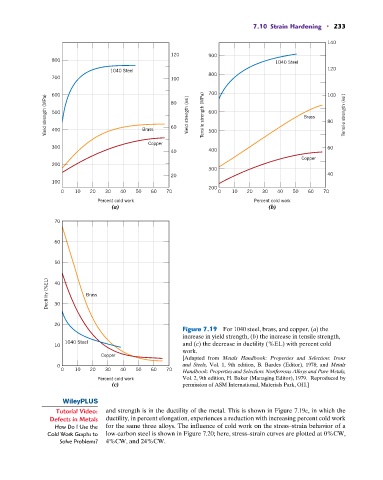

Figure 7.19 For 1040 steel, brass, and copper, (a) the

increase in yield strength, (b) the increase in tensile strength,

1040 Steel and (c) the decrease in ductility (%EL) with percent cold

10

work.

Copper

[Adapted from Metals Handbook: Properties and Selection: Irons

0 and Steels, Vol. 1, 9th edition, B. Bardes (Editor), 1978; and Metals

0 10 20 30 40 50 60 70 Handbook: Properties and Selection: Nonferrous Alloys and Pure Metals,

Percent cold work Vol. 2, 9th edition, H. Baker (Managing Editor), 1979. Reproduced by

(c) permission of ASM International, Materials Park, OH.]

Tutorial Video: and strength is in the ductility of the metal. This is shown in Figure 7.19c, in which the

Defects in Metals ductility, in percent elongation, experiences a reduction with increasing percent cold work

How Do I Use the for the same three alloys. The influence of cold work on the stress–strain behavior of a

Cold Work Graphs to low-carbon steel is shown in Figure 7.20; here, stress–strain curves are plotted at 0%CW,

Solve Problems? 4%CW, and 24%CW.