Page 96 - Materials Chemistry, Second Edition

P. 96

83

2.3. The Crystalline State

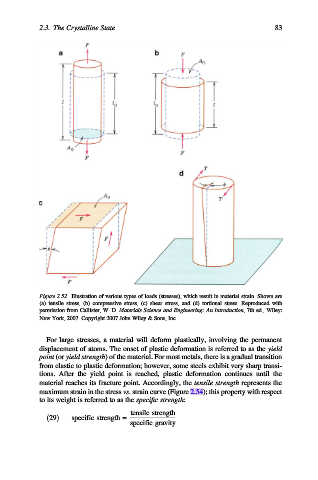

Figure 2.52. Illustration of various types of loads (stresses), which result in material strain. Shown are

(a) tensile stress, (b) compressive stress, (c) shear stress, and (d) tortional stress. Reproduced with

permission from Callister, W. D. Materials Science and Engineering: An Introduction, 7th ed., Wiley:

New York, 2007. Copyright 2007 John Wiley & Sons, Inc.

For large stresses, a material will deform plastically, involving the permanent

displacement of atoms. The onset of plastic deformation is referred to as the yield

point (or yield strength) of the material. For most metals, there is a gradual transition

from elastic to plastic deformation; however, some steels exhibit very sharp transi-

tions. After the yield point is reached, plastic deformation continues until the

material reaches its fracture point. Accordingly, the tensile strength represents the

maximum strain in the stress vs. strain curve (Figure 2.54); this property with respect

to its weight is referred to as the specific strength:

tensile strength

ð29Þ specific strength =

specific gravity