Page 100 - Mechanical Engineer's Data Handbook

P. 100

APPLIED MECHANICS 89

2.8.6 Cone clutch

By angling the contacting surfaces, the torque capacity

is increased; for example, for an angle of 9.6" the

capacity is increased by a factor of 6.

O=cone angle (to the shaft axis, from 8' upwards).

The theory is the same as for the disk clutch but with an

effective coefficient of friction

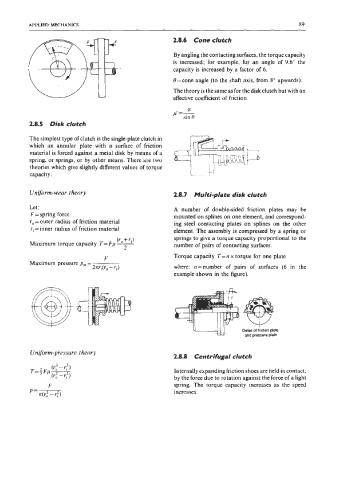

2.8.5 Disk clutch

The simplest type of clutch is the single-plate clutch in

which an annular plate with a surface of friction

material is forced against a metal disk by means of a

spring, or springs, or by other means. There are two

theories which give slightly different values of torque

capacity.

Uniform-wear theory 2.8.7 Multi-plate disk clutch

Let: A number of double-sided friction plates may be

F = spring force mounted on splines on one element, and correspond-

r, =outer radius of friction material ing steel contacting plates on splines on the other

ri =inner radius of friction material element. The assembly is compressed by a spring or

springs to give a torque capacity proportional to the

Maximum torque capacity T= Fp- (ro + Ti) number of pairs of contacting surfaces.

2

F Torque capacity T= n x torque for one plate

Maximum pressure pm =

2nri(ro-vi) where: n=number of pairs of surfaces (6 in the

example shown in the figure).

U7u

Detail of iiction plate

and pressure plate

Uniform-pressure theory

2.8.8 Centrifugal clutch

Internally expanding friction shoes are held in contact,

by the force due to rotation against the force of a light

spring. The torque capacity increases as the speed

increases.