Page 96 - Mechanical Engineer's Data Handbook

P. 96

APPLIED MECHANICS 85

where: /3= half angle of thread.

Example For /l=30", pe=1.155p.

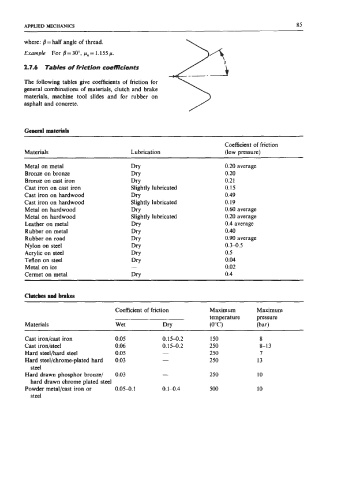

2.7.6 Tables of friction coentcients

The following tables give coefficients of friction for

general combinations of materials, clutch and brake

materials, machine tool slides and for rubber on

asphalt and concrete.

Coefficient of friction

Materials Lubrication (low pressure)

Metal on metal Dry 0.20 average

Bronze on bronze Dry 0.20

Bronze on cast iron Dry 0.21

Cast iron on cast iron Slightly lubricated 0.15

Cast iron on hardwood Dry 0.49

Cast iron on hardwood Slightly lubricated 0.19

Metal on hardwood Dry 0.60 average

Metal on hardwood Slightly lubricated 0.20 average

Leather on metal Dry 0.4 average

Rubber on metal Dry 0.40

Rubber on road Dry 0.90 average

Nylon on steel Dry 0.3-0.5

Acrylic on steel Dry 0.5

Teflon on steel Dry 0.04

Metal on ice - 0.02

Cermet on metal Dry 0.4

Coefficient of friction Maximum Maximum

temperature pressure

Materials Wet Dry (0°C) (bar)

Cast iron/cast iron 0.05 0.15-0.2 150 8

Cast iron/steel 0.06 0.15-0.2 250 8-13

Hard steel/hard steel 0.05 - 250 7

Hard steel/chrome-plated hard 0.03 - 250 13

steel

Hard drawn phosphor bronze/ 0.03 - 250 10

hard drawn chrome plated steel

Powder metal/cast iron or 0.05-0.1 0.1-0.4 500 10

steel