Page 97 - Mechanical Engineer's Data Handbook

P. 97

86 MECHANICAL ENGINEER’S DATA HANDBOOK

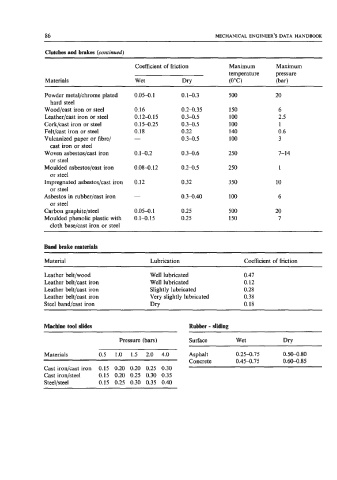

Clutches and brakes (continued)

Coefficient of friction Maximum Maximum

temperature pressure

Materials Wet Dry (O°C) (bar)

Powder metal/chrome plated 0.05-0.1 0.1-0.3 500 20

hard steel

Wood/cast iron or steel 0.16 0.2-0.35 150 6

Leather/cast iron or steel 0.12-0.15 0.3-0.5 100 2.5

Cork/cast iron or steel 0.15-0.25 0.3-0.5 100 1

Felt/cast iron or steel 0.18 0.22 140 0.6

Vulcanized paper or fibre/ 0.3-0.5 100 3

cast iron or steel

Woven asbestos/cast iron 0.1-0.2 0.3-0.6 250 7-14

or steel

Moulded asbestos/cast iron 0.08-0.12 0.2-0.5 250 1

or steel

Impregnated asbestos/cast iron 0.12 0.32 350 10

or steel

Asbestos in rubber/cast iron 0.3-0.40 100 6

or steel

Carbon graphite/steel 0.05-0.1 0.25 500 20

Moulded phenolic plastic with 0.1-0.1 5 0.25 150 7

cloth base/cast iron or steel

Band brake materials

Material Lubrication Coefficient of friction

Leather belt/wood Well lubricated 0.47

Leather belt/cast iron Well lubricated 0.12

Leather belt/cast iron Slightly lubricated 0.28

Leather belt/cast iron Very slightly lubricated 0.38

Steel band/cast iron Dry 0.18

Machine tool slii Rubber - sliding

~ ~

Pressure (bars) Surface Wet Dry

Materials 0.5 1.0 1.5 2.0 4.0 Asphalt 0.254.75 0.50-0.80

Concrete 0.45-0.75 0.60-0.85

Cast iron/cast iron 0.15 0.20 0.20 0.25 0.30

Cast iron/steel 0.15 0.20 0.25 0.30 0.35

Steel/steel 0.15 0.25 0.30 0.35 0.40