Page 271 - Mechanical Engineer's Data Handbook

P. 271

ENGINEERING MATERIALS 259

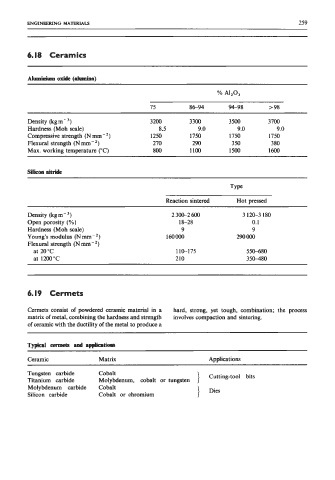

6.18 Ceramics

Aimmimum oxide (alumina)

% Al,O,

75 86-94 94-98 > 98

Density (kgmW3) 3200 3300 3500 3700

Hardness (Moh scale) 8.5 9.0 9.0 9.0

Compressive strength (N mm-2) 1250 1750 1750 1750

Flexural strength (Nmm-2) 270 290 350 380

Max. working temperature (“C) 800 1100 1500 1600

Reaction sintered Hot pressed

Density (kgm-,) 2 300-2 600 3 120-3 180

Open porosity (YO) 18-28 0.1

Hardness (Moh scale) 9 9

Young’s modulus (N mrnw2) 160000 290000

Flexural strength (Nmm-2)

at 20°C 110-175 550-680

at 1200 “C 210 350-480

6.19 Cermets

Cermets consist of powdered ceramic material in a hard, strong, yet tough, combination; the process

matrix of metal, combining the hardness and strength involves compaction and sintering.

of ceramic with the ductility of the metal to produce a

Ceramic Matrix Applications

Tungsten carbide Cobalt } Cutting-tool bits

Titanium carbide Molybdenum, cobalt or tungsten

Molybdenum carbide Cobalt }

Silicon carbide Cobalt or chromium Dies