Page 272 - Mechanical Engineer's Data Handbook

P. 272

260 MECHANICAL ENGINEER’S DATA HANDBOOK

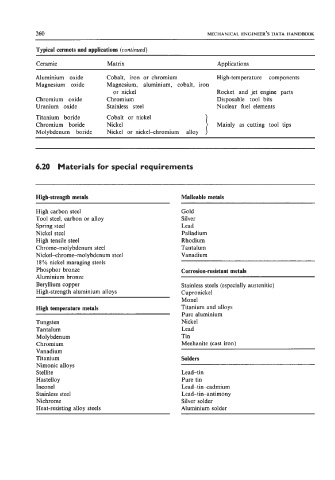

Typical cermets and applications (continued)

Ceramic Matrix Applications

Aluminium oxide Cobalt, iron or chromium High-temperature components

Magnesium oxide Magnesium, aluminium, cobalt, iron

or nickel Rocket and jet engine parts

Chromium oxide Chromium Disposable tool bits

Uranium oxide Stainless steel Nuclear fuel elements

Titanium boride Cobalt or nickel

Chromium boride Nickel Mainly as cutting tool tips

Molybdenum boride Nickel or nickel-chromium alloy

6.20 Materials for special requirements

High-strength metals Malleable metals

High carbon steel Gold

Tool steel, carbon or alloy Silver

Spring steel Lead

Nickel steel Palladium

High tensile steel Rhodium

Chrome-molybdenum steel Tantalum

Nickekhrome-molybdenum steel Vanadium

18% nickel maraging steels

Phosphor bronze Corrosion-resistant metals

Aluminium bronze

Beryllium copper Stainless steels (especially austenitic)

High-strength aluminium alloys Cupronickel

Monel

High temperature metals Titanium and alloys

Pure aluminium

Tungsten Nickel

Tantalum Lead

Molybdenum Tin

Chromium Meehanite (cast iron)

Vanadium

Titanium Solders

Nimonic alloys

Stellite Lead-tin

Hastelloy Pure tin

Inconel Lead-tinxadmium

Stainless steel Lead-tin-antimon y

Nichrome Silver solder

Heat-resisting alloy steels Aluminium solder