Page 90 - Mechanical Engineers' Handbook (Volume 2)

P. 90

3 The Resistance Strain Gage 79

Strain gages are seldom damaged by excitation voltages in excess of proper values, but

performance degrades. The voltage applied to a strain gage bridge creates a power loss in

each arm which must be dissipated in the form of heat. By its basic design, all of the power

input to the bridge is dissipated in the bridge with none available to the output circuit. The

sensing grid of every strain gage then operates at a higher temperature than the transducer

flexure to which it is bonded. The heat generated within the gage must be transferred by

conduction to the flexure. Heat flow into the flexure causes a temperature rise which is a

function of its heat sink capacity and gage power level. The optimum excitation level for

strain gage applications is a function of the strain gage grid area, gage resistance, heat sink

properties of the mounting surface, environmental operating temperature range of the gage

installation, required operational specifications, and installation and wiring techniques. Rigid

operating requirements for precision transducers require performance verification of the op-

timum excitation level. Zero shift versus load and stability under load at the maximum

operating temperature are the performance tests most sensitive to excessive excitation volt-

age.

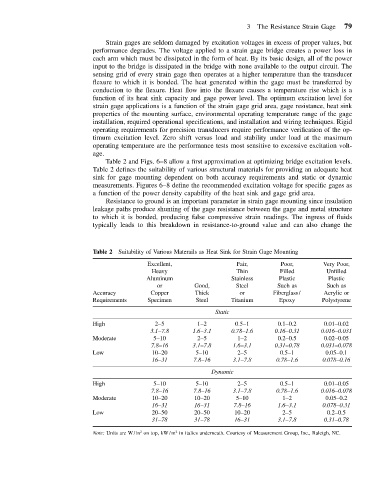

Table 2 and Figs. 6–8 allow a first approximation at optimizing bridge excitation levels.

Table 2 defines the suitability of various structural materials for providing an adequate heat

sink for gage mounting dependent on both accuracy requirements and static or dynamic

measurements. Figures 6–8 define the recommended excitation voltage for specific gages as

a function of the power density capability of the heat sink and gage grid area.

Resistance to ground is an important parameter in strain gage mounting since insulation

leakage paths produce shunting of the gage resistance between the gage and metal structure

to which it is bonded, producing false compressive strain readings. The ingress of fluids

typically leads to this breakdown in resistance-to-ground value and can also change the

Table 2 Suitability of Various Materails as Heat Sink for Strain Gage Mounting

Excellent, Fair, Poor, Very Poor,

Heavy Thin Filled Unfilled

Aluminum Stainless Plastic Plastic

or Good, Steel Such as Such as

Accuracy Copper Thick or Fiberglass/ Acrylic or

Requirements Specimen Steel Titanium Epoxy Polystyrene

Static

High 2–5 1–2 0.5–1 0.1–0.2 0.01–0.02

3.1–7.8 1.6–3.1 0.78–1.6 0.16–0.31 0.016–0.031

Moderate 5–10 2–5 1–2 0.2–0.5 0.02–0.05

7.8–16 3.1–7.8 1.6–3.1 0.31–0.78 0.031–0.078

Low 10–20 5–10 2–5 0.5–1 0.05–0.1

16–31 7.8–16 3.1–7.8 0.78–1.6 0.078–0.16

Dynamic

High 5–10 5–10 2–5 0.5–1 0.01–0.05

7.8–16 7.8–16 3.1–7.8 0.78–1.6 0.016–0.078

Moderate 10–20 10–20 5–10 1–2 0.05–0.2

16–31 16–31 7.8–16 1.6–3.1 0.078–0.31

Low 20–50 20–50 10–20 2–5 0.2–0.5

31–78 31–78 16–31 3.1–7.8 0.31–0.78

2

2

Note: Units are W/in on top, kW/m in italics underneath. Courtesy of Measurement Group, Inc., Raleigh, NC.