Page 412 - Mechanical Engineers' Handbook (Volume 4)

P. 412

3 Thermal Control Techniques 401

3 THERMAL CONTROL TECHNIQUES

3.1 Extended Surface and Heat Sinks

The heat flux from a surface, q/A, can be reduced if the surface area A is increased. The

use of extended surface or fins in a common method of achieving this reduction. Another

way of looking at this is through the use of Newton’s law of cooling:

q hA

T (72)

and considering that

T can be reduced for a given heat flow q by increasing h, which is

difficult for a specified coolant, or by increasing the surface area A.

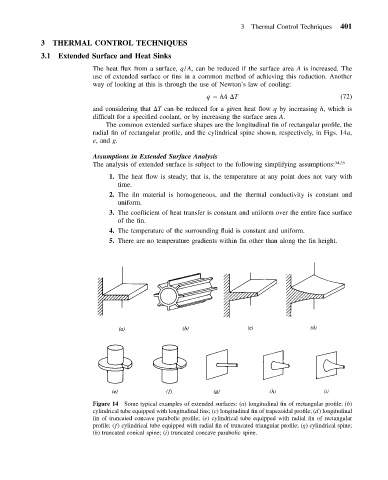

The common extended surface shapes are the longitudinal fin of rectangular profile, the

radial fin of rectangular profile, and the cylindrical spine shown, respectively, in Figs. 14a,

e, and g.

Assumptions in Extended Surface Analysis

The analysis of extended surface is subject to the following simplifying assumptions: 34,35

1. The heat flow is steady; that is, the temperature at any point does not vary with

time.

2. The fin material is homogeneous, and the thermal conductivity is constant and

uniform.

3. The coefficient of heat transfer is constant and uniform over the entire face surface

of the fin.

4. The temperature of the surrounding fluid is constant and uniform.

5. There are no temperature gradients within fin other than along the fin height.

Figure 14 Some typical examples of extended surfaces: (a) longitudinal fin of rectangular profile: (b)

cylindrical tube equipped with longitudinal fins; (c) longitudinal fin of trapezoidal profile; (d) longitudinal

fin of truncated concave parabolic profile; (e) cylindrical tube equipped with radial fin of rectangular

profile; (f) cylindrical tube equipped with radial fin of truncated triangular profile; (g) cylindrical spine;

(h) truncated conical spine; (i) truncated concave parabolic spine.