Page 391 - Mechanics of Asphalt Microstructure and Micromechanics

P. 391

Simulation of Asphalt Compaction 383

0.15 0.15

5:1 5:1

1:1 1:1

0.1 1:2 0.1 1:2

VVF VVF

0.05 0.05

0 0

0 1 2 3 4 5 6 7 8 9 10 11 12 0 1 2 3 4 5 6 7 8 9 10 11 12

Passage Passage

(a) (b)

0.15

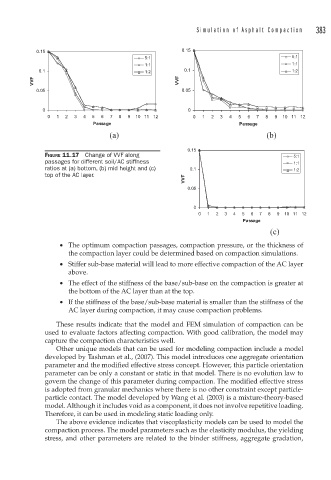

FIGURE 11.17 Change of VVF along 5:1

passages for different soil/AC stiffness 1:1

ratios at (a) bottom, (b) mid height and (c) 0.1 1:2

top of the AC layer.

VVF

0.05

0

0 1 2 3 4 5 6 7 8 9 10 11 12

Passage

(c)

• The optimum compaction passages, compaction pressure, or the thickness of

the compaction layer could be determined based on compaction simulations.

• Stiffer sub-base material will lead to more effective compaction of the AC layer

above.

• The effect of the stiffness of the base/sub-base on the compaction is greater at

the bottom of the AC layer than at the top.

• If the stiffness of the base/sub-base material is smaller than the stiffness of the

AC layer during compaction, it may cause compaction problems.

These results indicate that the model and FEM simulation of compaction can be

used to evaluate factors affecting compaction. With good calibration, the model may

capture the compaction characteristics well.

Other unique models that can be used for modeling compaction include a model

developed by Tashman et al., (2007). This model introduces one aggregate orientation

parameter and the modified effective stress concept. However, this particle orientation

parameter can be only a constant or static in that model. There is no evolution law to

govern the change of this parameter during compaction. The modified effective stress

is adopted from granular mechanics where there is no other constraint except particle-

particle contact. The model developed by Wang et al. (2003) is a mixture-theory-based

model. Although it includes void as a component, it does not involve repetitive loading.

Therefore, it can be used in modeling static loading only.

The above evidence indicates that viscoplasticity models can be used to model the

compaction process. The model parameters such as the elasticity modulus, the yielding

stress, and other parameters are related to the binder stiffness, aggregate gradation,