Page 419 - Mechanics of Asphalt Microstructure and Micromechanics

P. 419

Characterization and Modeling Anisotropic Proper ties of Asphalt Concrete 411

compressive modulus nor a tensile modulus. More sophisticated analysis is necessary

for interpreting the stress and strain distribution and evaluating the modulus in ten-

sion and compression in the IDT configuration.

Most previous research has measured the moduli in tension and compression by

applying tensile and compressive loads on different sets of asphalt mixture specimens

and investigated the bimodularity by comparing the mean values from these sets. Con-

sidering the limited accuracy for dynamic modulus tests (Table 2 of AASHTO TP62),

and the difficulty in conducting a dynamic modulus test in tension, a more convenient

testing procedure is necessary. It is advantageous to develop an experiment measuring

both moduli from the same specimen and at the same time to minimize experimental

efforts and effects induced due to the use of different samples. This section describes a

study on determining the moduli in tension and compression from a simply supported

asphalt mixture beam.

12.7.1 Testing Setup and Procedure

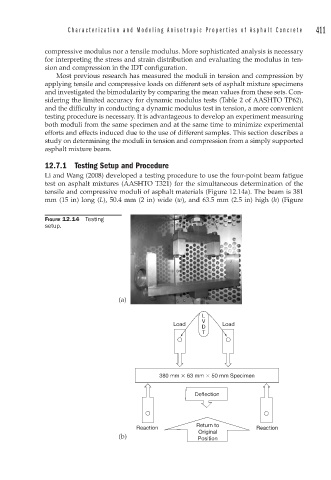

Li and Wang (2008) developed a testing procedure to use the four-point beam fatigue

test on asphalt mixtures (AASHTO T321) for the simultaneous determination of the

tensile and compressive moduli of asphalt materials (Figure 12.14a). The beam is 381

mm (15 in) long (L), 50.4 mm (2 in) wide (w), and 63.5 mm (2.5 in) high (h) (Figure

FIGURE 12.14 Testing

setup.

(a)

L

V

Load Load

D

T

380 mm 63 mm 50 mm Specimen

Deflection

Return to

Reaction Reaction

Original

(b) Position