Page 480 - Mechanics of Asphalt Microstructure and Micromechanics

P. 480

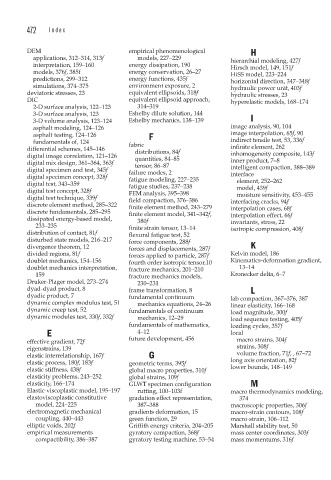

472 Index

DEM empirical phenomenological H

applications, 312–314, 313f models, 227–229 hierarchial modeling, 427f

interpretation, 159–160 energy dissipation, 190 Hirsch model, 149, 151f

models, 376f, 385f energy conservation, 26–27 HiSS model, 223–224

predictions, 299–312 energy functions, 435f horizontal direction, 347–348f

simulations, 374–375 environment exposure, 2 hydraulic power unit, 403f

deviatoric stresses, 23 equivalent ellipsoids, 318f hydraulic stresses, 23

DIC equivalent ellipsoid approach, hyperelastic models, 168–174

2-D surface analysis, 122–123 314–319

3-D surface analysis, 123 Eshelby dilute solution, 144

3-D volume analysis, 123–124 Eshelby mechanics, 138–139 I

asphalt modeling, 124–126 image analysis, 90, 104

asphalt testing, 124–126 F image interpolation, 65f, 90

fundamentals of, 124 fabric indirect tensile test, 53, 336f

differential schemes, 145–146 distributions, 84f infinite element, 262

digital image correlation, 121–126 quantities, 84–85 inhomogeneity composite, 143f

digital mix design, 361–364, 363f tensor, 86–87 inner product, 7–8

digital specimen and test, 345f failure modes, 2 intelligent compaction, 388–389

digital specimen concept, 328f fatigue modeling, 227–235 interface

digital test, 343–359 fatigue studies, 237–238 element, 252–262

digital test concept, 328f FEM analysis, 395–398 model, 439f

moisture sensitivity, 453–455

digital test technique, 339f field compaction, 376–386 interfacing cracks, 94f

discrete element method, 285–322 finite element method, 243–279

discrete fundamentals, 285–295 finite element model, 341–342f, interpolation cases, 68f

interpolation effect, 66f

dissipated energy-based model, 380f invariants, stress, 22

233–235 finite strain tensor, 13–14 isotropic compression, 408f

distribution of contact, 81f flexural fatigue test, 52

disturbed state models, 216–217 force components, 288f

divergence theorem, 12 forces and displacements, 287f K

divided regions, 81f forces applied to particle, 287f Kelvin model, 186

doublet mechanics, 154–156 fourth order isotropic tensor,10 Kinematics-deformation gradient,

doublet mechanics interpretation, fracture mechanics, 201–210 13–14

159 fracture mechanics models, Kronecker delta, 6–7

Druker-Plager model, 273–274 230–231

dyad-dyad product, 8 frame transformation, 8 L

dyadic product, 7 fundamental continuum lab compaction, 367–376, 387

dynamic complex modulus test, 51 mechanics equations, 24–26 linear elasticity, 166–168

dynamic creep test, 52 fundamentals of continuum load magnitude, 300f

dynamic modules test, 330f, 332f mechanics, 12–29 load sequence testing, 405f

fundamentals of mathematics, loading cycles, 357f

E 4–12 local

effective gradient, 72f future development, 456 macro strains, 304f

eigenstrains, 139 strains, 308f

elastic interrelationship, 167f G volume fraction, 71f, , 67–72

elastic process, 180f, 183f geometric terms, 395f long axis orientation, 82f

elastic stiffness, 438f global macro properties, 310f lower bounds, 148–149

elasticity problems, 243–252 global strains, 109f

elasticity, 166–174 GLWT specimen configuration M

Elastic-viscoplastic model, 195–197 rutting, 100–103f macro thermodynamics modeling,

elastoviscoplastic constitutive gradation effect representation, 374

model, 224–225 387–388 macroscopic properties, 306f

electromagnetic mechanical gradients deformation, 15 macro-strain contours, 108f

coupling, 440–443 green function, 29 macro-strain, 106–112

elliptic voids, 202f Griffith energy criteria, 204–205 Marshall stability test, 50

empirical measurements gyratory compaction, 368f mass center coordinates, 303f

compactibility, 386–387 gyratory testing machine, 53–54 mass momentums, 316f