Page 183 - Mechanics of Microelectromechanical Systems

P. 183

170 Chapter 3

By also using the other numerical values, one can study the sagittal-to-

folded-beam stiffness ratio which is plotted in Fig. 3.39 as a function of

the length of the folded beam. It can be seen that the sagittal design is

approximately 2.5 times stiffer than a corresponding folded-beam

configuration for small lengths of the middle compliant leg.

3. MICROSUSPENSIONS FOR ROTARY MOTION

Several microsuspensions are studied in this section, which are designed

for implementation in rotary-motion micromechanisms. Similar to the

microsuspension configurations that are used in linear-motion applications

and which were shown to be able to accommodate rotary motion as well, the

rotary microsprings can also be sensitive to linear motion.

3.1 Curved-Beam Springs

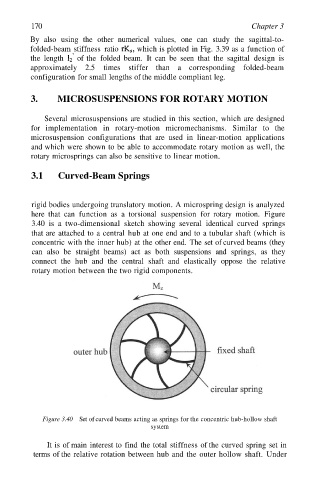

rigid bodies undergoing translatory motion. A microspring design is analyzed

here that can function as a torsional suspension for rotary motion. Figure

3.40 is a two-dimensional sketch showing several identical curved springs

that are attached to a central hub at one end and to a tubular shaft (which is

concentric with the inner hub) at the other end. The set of curved beams (they

can also be straight beams) act as both suspensions and springs, as they

connect the hub and the central shaft and elastically oppose the relative

rotary motion between the two rigid components.

Figure 3.40 Set of curved beams acting as springs for the concentric hub-hollow shaft

system

It is of main interest to find the total stiffness of the curved spring set in

terms of the relative rotation between hub and the outer hollow shaft. Under