Page 331 - Mechanics of Microelectromechanical Systems

P. 331

318 Chapter 5

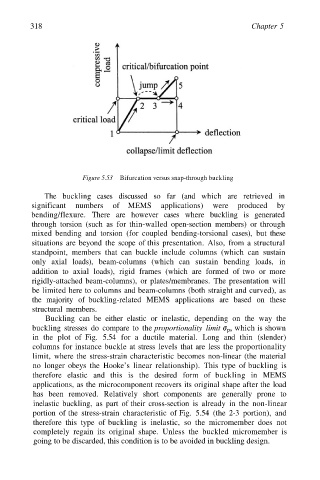

Figure 5.53 Bifurcation versus snap-through buckling

The buckling cases discussed so far (and which are retrieved in

significant numbers of MEMS applications) were produced by

bending/flexure. There are however cases where buckling is generated

through torsion (such as for thin-walled open-section members) or through

mixed bending and torsion (for coupled bending-torsional cases), but these

situations are beyond the scope of this presentation. Also, from a structural

standpoint, members that can buckle include columns (which can sustain

only axial loads), beam-columns (which can sustain bending loads, in

addition to axial loads), rigid frames (which are formed of two or more

rigidly-attached beam-columns), or plates/membranes. The presentation will

be limited here to columns and beam-columns (both straight and curved), as

the majority of buckling-related MEMS applications are based on these

structural members.

Buckling can be either elastic or inelastic, depending on the way the

buckling stresses do compare to the proportionality limit which is shown

in the plot of Fig. 5.54 for a ductile material. Long and thin (slender)

columns for instance buckle at stress levels that are less the proportionality

limit, where the stress-strain characteristic becomes non-linear (the material

no longer obeys the Hooke’s linear relationship). This type of buckling is

therefore elastic and this is the desired form of buckling in MEMS

applications, as the microcomponent recovers its original shape after the load

has been removed. Relatively short components are generally prone to

inelastic buckling, as part of their cross-section is already in the non-linear

portion of the stress-strain characteristic of Fig. 5.54 (the 2-3 portion), and

therefore this type of buckling is inelastic, so the micromember does not

completely regain its original shape. Unless the buckled micromember is

going to be discarded, this condition is to be avoided in buckling design.