Page 143 - Mechatronics for Safety, Security and Dependability in a New Era

P. 143

Ch26-I044963.fm Page 127 Tuesday, August 1, 2006 3:00 PM

3:00 PM

Tuesday, August 1, 2006

Page 127

Ch26-I044963.fm

127

127

Rigid translational

Contact finger 1 Rigid translational Contact

Contact finger 1

driving joint

driving joint Contact

Rigid rotational finger 1 92.3 mm

Rigid rotational

driving joint Rigid rotational free Y

driving joint

Rigid rotational free

60.0°

joint by a contact plate

Contact

Contact joint by a contact plate Veo.r

with a thin rubber

finger 4

finger 4 with a thin rubber

Work (12, 35) 92.1 mm

12, 35)

Work

Contact

Contact Contact (35, 12)

(35, 12)

finger 4

finger 2 finger 4 62.2°

O O X X

Elastic rotational free 91.8 mm (-35, 10) Contact

Elastic rotational free

Contact

91.8 mm

-35,

10)

joint by a contact plate

joint by a contact plate (-10, 35 finger 2

finger 2

(-10, 35)

63.8°

with a thick rubber 63.8°

with a thick rubber

Rigid rotational

Rigid rotational

/ driving joint 53.3°

driving joint

Elastic translational driving joint

Elastic translational driving joint

92.0 mm Contact

Contact

finger 3

finger 3

Contact finger 3

Contact finger 3

(a) Characteristic of each joint (b) Coordinates of each contact point in experiments

(a) Characteristic of each joint (b) Coordinates of each contact point in experiments

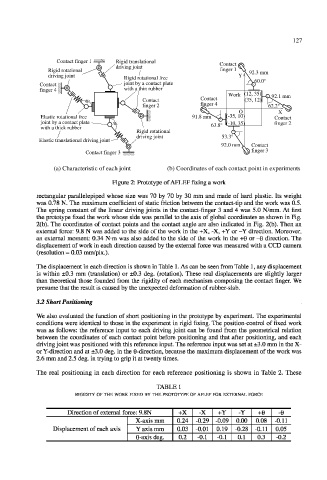

Figure 2: Prototype of AFLEF fixing a work

rectangular parallelepiped whose size was 70 by 70 by 30 mm and made of hard plastic. Its weight

was 0.78 N. The maximum coefficient of static friction between the contact-tip and the work was 0.5.

The spring constant of the linear driving joints in the contact-finger 3 and 4 was 5.0 N/mm. At first

the prototype fixed the work whose side was parallel to the axis of global coordinates as shown in Fig.

2(b). The coordinates of contact points and the contact angle are also indicated in Fig. 2(b). Then an

external force: 9.8 N was added to the side of the work in the +X, -X, +Y or -Y direction. Moreover,

an external moment: 0.34 N-m was also added to the side of the work in the +6 or -6 direction. The

displacement of work in each direction caused by the external force was measured with a CCD camera

(resolution = 0.03 mm/pix.).

The displacement in each direction is shown in Table 1. As can be seen from Table 1, any displacement

is within ±0.3 mm (translation) or ±0.3 deg. (rotation). These real displacements are slightly larger

than theoretical those founded from the rigidity of each mechanism composing the contact finger. We

presume that the result is caused by the unexpected deformation of rubber-slab.

3.2 Short Positioning

We also evaluated the function of short positioning in the prototype by experiment. The experimental

conditions were identical to those in the experiment in rigid fixing. The position-control of fixed work

was as follows: the reference input to each driving joint can be found from the geometrical relation

between the coordinates of each contact point before positioning and that after positioning, and each

driving joint was positioned with this reference input. The reference input was set at ±3.0 mm in the X-

or Y-direction and at ±3.0 deg. in the 0-direction, because the maximum displacement of the work was

2.6 mm and 2.5 deg. in trying to grip it at twenty times.

The real positioning in each direction for each reference positioning is shown in Table 2. These

TABLE 1

RIGIDITY OF THE WORK FIXED BY THE PROTOTYPE OF AFLEF FOR EXTERNAL FORCE

Direction of external force: 9.8N +X -X +Y -Y +0 -e

X-axis mm 0.24 -0.29 -0.09 0.00 0.08 -0.11

Displacement of each axis Y axis mm 0.03 -0.01 0.19 -0.28 -0.11 0.05

0-axis deg. 0.2 -0.1 -0.1 0.1 0.3 -0.2