Page 146 - Mechatronics for Safety, Security and Dependability in a New Era

P. 146

Ch27-I044963.fm Page 130 Monday, August 7, 2006 11:26 AM

Ch27-I044963.fm

130

130 Page 130 Monday, August 7,2006 11:26 AM

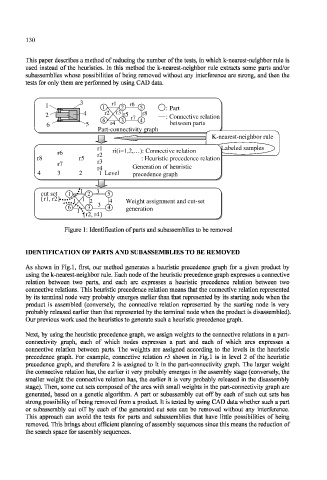

This paper describes a method of reducing the number of the tests, in which k-nearest-neighbor rule is

used instead of the heuristics. In this method the k-nearest-neighbor rule extracts some parts and/or

subassemblies whose possibilities of being removed without any interference are strong, and then the

tests for only them are performed by using CAD data.

3 r1

1 r6

: Part t

1 2 5 5:Par

2 4 r2 r3 r5 r7 r8 —: : Connective relation

Connective relation

6 3 4

between parts

6 5 r4 between parts

Part-connectivity graph

Part-connectivity graph

rule

K-nearest-neighbor

3 K-nearest-neighbor rule

_L

Labeled samples

T r1 Labeled samples

ri(i=1,2,…): Connective relation

}_

r6 r6 r2 ri(i=1,2,…): Connective relation

r8 r8 r5 r5 , : Heuristic precedence relation

: Heuristic precedence relation

r7 r7 r3 Generation of heuristic

Generation of heuristic

r r4 4

4 4 3 3 2 2 1 1 Level precedence graph

Level

precedence graph

3 J

cut set t 1 1 1 1 £ 7©- -© >

2

5

cut s e

{r1, r2} 1 1 2 4 Weight assignment and cut-set

{r1, r2>..V^Tv

Weight assignment and cut-set

6 3 3 4 generation

1 |V®-^-© generation

{r2, r4}

{r2, r4}

Figure 1: Identification of parts and subassemblies to be removed

IDENTIFICATION OF PARTS AND SUBASSEMBLIES TO BE REMOVED

As shown in Fig.l, first, our method generates a heuristic precedence graph for a given product by

using the k-nearest-neighbor rule. Each node of the heuristic precedence graph expresses a connective

relation between two parts, and each arc expresses a heuristic precedence relation between two

connective relations. This heuristic precedence relation means that the connective relation represented

by its terminal node very probably emerges earlier than that represented by its starting node when the

product is assembled (conversely, the connective relation represented by the starting node is very

probably released earlier than that represented by the terminal node when the product is disassembled).

Our previous work used the heuristics to generate such a heuristic precedence graph.

Next, by using the heuristic precedence graph, we assign weights to the connective relations in a part-

connectivity graph, each of which nodes expresses a part and each of which arcs expresses a

connective relation between parts. The weights are assigned according to the levels in the heuristic

precedence graph. For example, connective relation r5 shown in Fig. 1 is in level 2 of the heuristic

precedence graph, and therefore 2 is assigned to it in the part-connectivity graph. The larger weight

the connective relation has, the earlier it very probably emerges in the assembly stage (conversely, the

smaller weight the connective relation has, the earlier it is very probably released in the disassembly

stage). Then, some cut sets composed of the arcs with small weights in the part-connectivity graph are

generated, based on a genetic algorithm. A part or subassembly cut off by each of such cut sets has

strong possibility of being removed from a product. It is tested by using CAD data whether such a part

or subassembly cut off by each of the generated cut sets can be removed without any interference.

This approach can avoid the tests for parts and subassemblies that have little possibilities of being

removed. This brings about efficient planning of assembly sequences since this means the reduction of

the search space for assembly sequences.