Page 150 - Mechatronics for Safety, Security and Dependability in a New Era

P. 150

Ch28-I044963.fm Page 134 Thursday, July 27, 2006 7:12 AM

Ch28-I044963.fm

134

134 Page 134 Thursday, July 27, 2006 7:12 AM

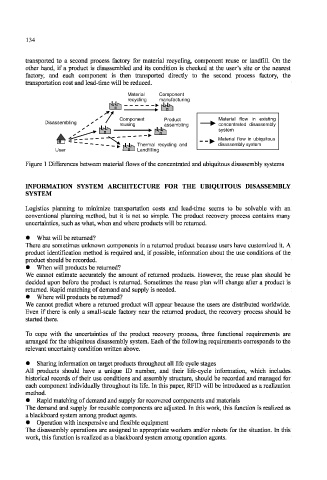

transported to a second process factory for material recycling, component reuse or landfill. On the

other hand, if a product is disassembled and its condition is checked at the user's site or the nearest

factoiy, and each component is then transported directly to the second process factory, the

transportation cost and lead-time will be reduced.

Material Component

Component

manufacturing

recycling manufacturing

Material flow in existing

Component Product Material flow in existing

Product

Disassembling

Disassembling

reusing assembling W' concentrated disassembly

assembling

concentrated disassembly

system

system

Material flow

_ _ ^ Material flow in ubiquitous

ubiquitous

in

Thermal recycling and disassembly system

disassembly system

and

recycling

Thermal

- • I

Landfilling

User

User 1 Landfilling

Figure 1 Differences between material flows of the concentrated and ubiquitous disassembly systems

INFORMATION SYSTEM ARCHITECTURE FOR THE UBIQUITOUS DISASSEMBLY

SYSTEM

Logistics planning to minimize transportation costs and lead-time seems to be solvable with an

conventional planning method, but it is not so simple. The product recovery process contains many

uncertainties, such as what, when and where products will be returned.

• What will be returned?

There are sometimes unknown components in a returned product because users have customized it. A

product identification method is required and, if possible, information about the use conditions of the

product should be recorded.

• When will products be returned?

We cannot estimate accurately the amount of returned products. However, the reuse plan should be

decided upon before the product is returned. Sometimes the reuse plan will change after a product is

returned. Rapid matching of demand and supply is needed.

• Where will products be returned?

We cannot predict where a returned product will appear because the users are distributed worldwide.

Even if there is only a small-scale factory near the returned product, the recovery process should be

started there.

To cope with the uncertainties of the product recovery process, three functional requirements are

arranged for the ubiquitous disassembly system. Each of the following requirements corresponds to the

relevant uncertainty condition written above.

• Sharing information on target products throughout all life cycle stages

All products should have a unique ID number, and their life-cycle information, which includes

historical records of their use conditions and assembly structure, should be recorded and managed for

each component individually throughout its life. In this paper, RFID will be introduced as a realization

method.

• Rapid matching of demand and supply for recovered components and materials

The demand and supply for reusable components are adjusted. Tn this work, this function is realized as

a blackboard system among product agents.

• Operation with inexpensive and flexible equipment

The disassembly operations are assigned to appropriate workers and/or robots for the situation. In this

work, this function is realized as a blackboard system among operation agents.