Page 154 - Mechatronics for Safety, Security and Dependability in a New Era

P. 154

Ch28-I044963.fm Page 138 Thursday, July 27, 2006 7:12 AM

Ch28-I044963.fm

138

138 Page 138 Thursday, July 27, 2006 7:12 AM

achieve it. However, the important effects of agent-based implementation will become apparent in

system reconfiguration. For example, in the case that we change a program in order to refer to an

additional database, in which not only the product data but also the processing program must be

modified, the agent-based system allows in-process modification in intelligible programming.

Moreover, the rum time processing load can be optionally distributed by modification of the agent

work place.

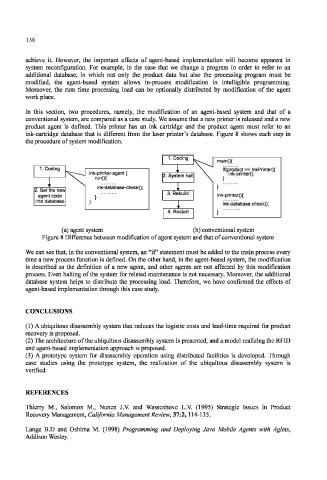

In this section, two procedures, namely, the modification of an agent-based system and that of a

conventional system, are compared as a case study. We assume that a new printer is released and a new

product agent is defined. This printer has an ink cartridge and the product agent must refer to an

ink-cartridge database that is different from the laser printer's database. Figure 8 shows each step in

the procedure of system modification.

1. Coding

main(){

1. Coding if(product == lnkPrinter){

ink-printer-agent { ink-printer();

run(){ 2. System halt

ink-database-check();

2. Set the new

agent code 3. Rebuild ink-printer(){

into database

ink-database-check();

4. Restart

(a) agent system (b) conventional system

Figure 8 Difference between modification of agent system and that of conventional system

We can see that, in the conventional system, an "if statement must be added to the main process every

time a new process function is defined. On the other hand, in the agent-based system, the modification

is described as the definition of a new agent, and other agents are not affected by this modification

process. Even halting of the system for related maintenance is not necessary. Moreover, the additional

database system helps to distribute the processing load. Therefore, we have confirmed the effects of

agent-based implementation through this case study.

CONCLUSIONS

(1) A ubiquitous disassembly system that reduces the logistic costs and lead-time required for product

recovery is proposed.

(2) The architecture of the ubiquitous disassembly system is presented, and a model realizing the RFID

and agent-based implementation approach is proposed.

(3) A prototype system for disassembly operation using distributed facilities is developed. Through

case studies using the prototype system, the realization of the ubiquitous disassembly system is

verified.

REFERENCES

Thierry M., Salomon M., Nunen J.V. and Wassenhove L.V. (1995) Strategic Issues in Product

Recovery Management, California Management Review, 37:2, 114-135.

Lange B.D and Oshima M. (1998) Programming and Deploying Java Mobile Agents with Aglets,

Addison Wesley.