Page 157 - Mechatronics for Safety, Security and Dependability in a New Era

P. 157

Ch29-I044963.fm Page 141 Tuesday, August 1, 2006 3:05 PM

Page 141

1, 2006

3:05 PM

Tuesday, August

Ch29-I044963.fm

141

141

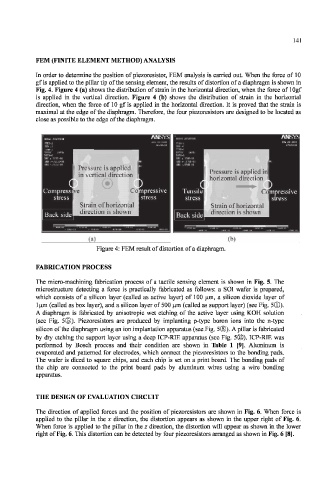

FEM (FINITE ELEMENT METHOD) ANALYSIS

In order to determine the position of piezoresistor, FEM analysis is carried out. When the force of 10

gf is applied to the pillar tip of the sensing element, the results of distortion of a diaphragm is shown in

Fig. 4. Figure 4 (a) shows the distribution of strain in the horizontal direction, when the force of lOgf

is applied in the vertical direction. Figure 4 (b) shows the distribution of strain in the horizontal

direction, when the force of 10 gf is applied in the horizontal direction. It is proved that the strain is

maximal at the edge of the diaphragm. Therefore, the four piezoresistors are designed to be located as

close as possible to the edge of the diaphragm.

ANSYS ANSYS

STEP=1

fcBsSM

SHX =.40DE-03 I

I Pressure is applied

in vertical direction Pressure is applied in

c ) K horizontal direction )

Co mpressive

Compressil-e ® r Tensile Compressive

stress stress stress stress

Strain of horizontal Strain of horizontal

Back side direction is shown Back side direction is shown

i

— - •

(a) (b)

Figure 4: FEM result of distortion of a diaphragm.

FABRICATION PROCESS

The micro-machining fabrication process of a tactile sensing element is shown in Fig. 5. The

microstructure detecting a force is practically fabricated as follows: a SOI wafer is prepared,

which consists of a silicon layer (called as active layer) of 100 urn, a silicon dioxide layer of

lum (called as box layer), and a silicon layer of 500 u.m (called as support layer) (see Fig. 5®).

A diaphragm is fabricated by anisotropic wet etching of the active layer using KOH solution

(see Fig. 5©). Piezoresistors are produced by implanting p-type boron ions into the n-type

silicon of the diaphragm using an ion implantation apparatus (see Fig. 5®). A pillar is fabricated

by dry etching the support layer using a deep ICP-RIE apparatus (see Fig. 5©). ICP-RIE was

performed by Bosch process and their condition are shown in Table 1 [9J. Aluminum is

evaporated and patterned for electrodes, which connect the piezoresistors to the bonding pads.

The wafer is diced to square chips, and each chip is set on a print board. The bonding pads of

the chip are connected to the print board pads by aluminum wires using a wire bonding

apparatus.

THE DESIGN OF EVALUATION CIRCUIT

The direction of applied forces and the position of piezoresistors are shown in Fig. 6. When force is

applied to the pillar in the x direction, the distortion appears as shown in the upper right of Fig. 6.

When force is applied to the pillar in the z direction, the distortion will appear as shown in the lower

right of Fig. 6. This distortion can be detected by four piezoresistors arranged as shown in Fig. 6 [8].