Page 159 - Mechatronics for Safety, Security and Dependability in a New Era

P. 159

Ch29-I044963.fm Page 143 Tuesday, August 1, 2006 3:05 PM

Tuesday, August

1, 2006

3:05 PM

Page 143

Ch29-I044963.fm

143

143

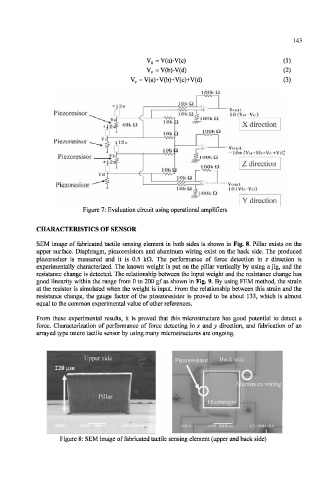

V x = V(a)-V(c) (1)

V Y = V(b)-V(d) (2)

V z = V(a)+V(b)+V(c)+V(d) (3)

look a

Piezoresisor

Piezoresisor

VouL

-10*(Va+Vh+Vc+Vd>

Piezoresisor

Piezoresisor

jlOOkfi

Y direction

Figure 7: Evaluation circuit using operational amplifiers

CHARACTERISTICS OF SENSOR

SEM image of fabricated tactile sensing element in both sides is shown in Fig. 8. Pillar exists on the

upper surface. Diaphragm, piezoresistors and aluminum wiring exist on the back side. The produced

piezoresitor is measured and it is 0.5 kfl. The performance of force detection in z direction is

experimentally characterized. The known weight is put on the pillar vertically by using a jig, and the

resistance change is detected. The relationship between the input weight and the resistance change has

good linearity within the range from 0 to 200 gf as shown in Fig. 9. By using FEM method, the strain

at the resistor is simulated when the weight is input. From the relationship between this strain and the

resistance change, the gauge factor of the pizezoresistor is proved to be about 133, which is almost

equal to the common experimental value of other references.

From these experimental results, it is proved that this microstructure has good potential to detect a

force. Characterization of performance of force detecting in x and y direction, and fabrication of an

arrayed type micro tactile sensor by using many microstructures are ongoing.

Figure 8: SEM image of fabricated tactile sensing element (upper and back side)