Page 152 - Mechatronics for Safety, Security and Dependability in a New Era

P. 152

Ch28-I044963.fm Page 136 Thursday, July 27, 2006 7:12 AM

Ch28-I044963.fm

136

136 Page 136 Thursday, July 27, 2006 7:12 AM

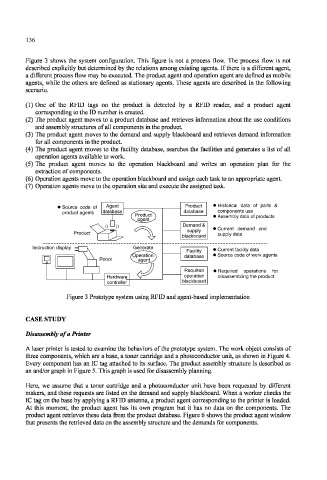

Figure 3 shows the system configuration. This figure is not a process flow. The process flow is not

described explicitly but determined by the relations among existing agents. If there is a different agent,

a different process flow may be executed. The product agent and operation agent are defined as mobile

agents, while the others are defined as stationary agents. These agents are described in the following

scenario.

(1) One of the RFID tags on the product is detected by a RFID reader, and a product agent

corresponding to the ID number is created.

(2) The product agent moves to a product database and retrieves information about the use conditions

and assembly structures of all components in the product.

(3) The product agent moves to the demand and supply blackboard and retrieves demand information

for all components in the product.

(4) The product agent moves to the facility database, searches the facilities and generates a list of all

operation agents available to work.

(5) The product agent moves to the operation blackboard and writes an operation plan for the

extraction of components.

(6) Operation agents move to the operation blackboard and assign each task to an appropriate agent.

(7) Operation agents move to the operation site and execute the assigned task.

Historical data of parts &

Source code of

I Source code of Agent Product • Historical data of parts &

components use

product agents

product agents database database components use

Product • Assembly data of products

Assembly data of products

agent

(( )) Demand &

Current demand and

supply »Current demand and

Product supply data

supply data

blackboard

Instruction display Generate

Instruction display

Current facility data

Facility > Current facility data

Source code of work agents

Operation database > Source code of work agents

Robot agent

Required • Required operations for

Required operations for

disassembling the product

Hardware operation disassembling the product

controller blackboard

Figure 3 Prototype system using RFID and agent-based implementation

CASE STUDY

Disassembly of a Printer

A laser printer is tested to examine the behaviors of the prototype system. The work object consists of

three components, which are a base, a toner cartridge and a photoconductor unit, as shown in Figure 4.

Every component has an IC tag attached to its surface. The product assembly structure is described as

an and/or graph in Figure 5. This graph is used for disassembly planning.

Here, we assume that a toner cartridge and a photoconductor unit have been requested by different

makers, and these requests are listed on the demand and supply blackboard. When a worker checks the

IC tag on the base by applying a RFID antenna, a product agent corresponding to the printer is loaded.

At this moment, the product agent has its own program but it has no data on the components. The

product agent retrieves these data from the product database. Figure 6 shows the product agent window

that presents the retrieved data on the assembly structure and the demands for components.