Page 232 - Mechatronics for Safety, Security and Dependability in a New Era

P. 232

Ch44-I044963.fm Page 216 Tuesday, August 1, 2006 4:00 PM

Ch44-I044963.fm

216

216 Page 216 Tuesday, August 1, 2006 4:00 PM

worst rule for storages. That means the best rule from view point of total manufacturing system

might not be the best for each area. Conversely, the best rale at an area might not be the global best

rule. It is important to evaluate the global manufacturing system for cutting total product cost. All

costs in assembly line are the same. We consider that the initial inventory level of parts storage is

enough to absorb the fluctuation of parts arrival from processing areas. Those facts also suggest the

importance of evaluating total manufacturing system.

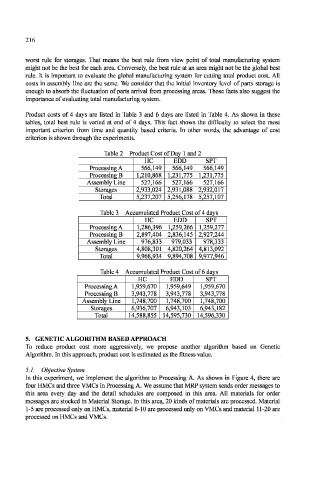

Product costs of 4 days are listed in Table 3 and 6 days are listed in Table 4. As shown in these

tables, total best rule is varied at end of 4 days. This fact shows the difficulty to select the most

important criterion from time and quantity based criteria. In other words, the advantage of cost

criterion is shown through the experiments.

Table 2 Product Cost of Day 1 am 2

HC EDD SPT

Processing A 566,149 566,149 566,149

Processing B 1,210,868 1,231,775 1,231,775

Assembly Line 527,166 527,166 527,166

Storages 2,933,024 2,931,088 2,932,017

Total 5,237,207 5,256,178 5,257,107

Table 3 Accumulated Product Cost of 4 days

HC EDD SPT

Processing A 1,286,396 1,259,266 1,259,277

Processing B 2,897,404 2,836,145 2,927,244

Assembly Line 976,833 979,033 978,333

Storages 4,808,301 4,820,264 4,813,092

Total 9,968,934 9,894,708 9,977,946

Table 4 Accumulated Product Cost of 6 days

HC EDD SPT

Processing A 1,959,670 1,959,649 1,959,670

Processing B 3,943,778 3,943,778 3,943,778

Assembly Line 1,748,700 1,748,700 1,748,700

Storages 6,936,707 6,943,103 6,943,182

Total 14,588,855 14,595,730 14,596,330

5. GENETIC ALGORITHM BASED APPROACH

To reduce product cost more aggressively, we propose another algorithm based on Genetic

Algorithm. In this approach, product cost is estimated as the fitness value.

5. /. Objective System

In this experiment, we implement the algorithm to Processing A. As shown in Figure 4, there are

four HMCs and three VMCs in Processing A. We assume that MRP system sends order messages to

this area every day and the detail schedules are composed in this area. All materials for order

messages are stocked in Material Storage. In this area, 20 kinds of materials are processed. Material

1-5 are processed only on HMCs, material 6-10 are processed only on VMCs and material 11-20 are

processed on HMCs and VMCs.