Page 364 - Mechatronics for Safety, Security and Dependability in a New Era

P. 364

Ch71-I044963.fm Page 348 Tuesday, August 1, 2006 4:45 PM

Ch71-I044963.fm

348

348 Page 348 Tuesday, August 1, 2006 4:45 PM

Conventionally the motor control is assumed to be a velocity controller of a motor. In that case the

vibrations of the tool mechanism, reel, gripper or any apparatus connected to the motor are not taken

into account. This might reduce the capability of the machine system to carry out its assignment and

impair the lifetime of the equipment. Nonetheless, it is usually more important to know how the load

of the motor behaves.

There are two complementary methods to improve the dynamic behaviour of the machine system. The

first is to make the mechanism more rigid, but this method usually makes the response slower. The

second is to take the dynamic behaviour of the mechanism into account in the control strategy. The

latter method is of interest to us. Motion control technologies have been widely used in industrial

applications. Due to the fact that good technologies allow for high productivity and products of high

quality, the study of motion control is a significant topic.

The aim of the proposed controller is to drive the load to a reference in such a way that the load

follows the desired value as rapidly and as accurately as possible, but without awkward vibration. One

of the most traditional methods to suppress resonance in the electromechanical system is to allow only

small and slow changes in the reference command. For example different kinds of filters are used in a

reference signal to suppress mechanical vibrations. Dumetz et al. (2001) have studied bi-quad and low

pass filters in a control loop but also as a reference filter. The closed loop filter makes possible to

compensate poles and zeros of the transfer function from the motor side, and the reference filter

compensates poles of the transfer function in the load side. Another widely used filter for vibration

suppression is the Notch filter (Ellis et al., 2000). The drawback of the filtering is the low sensitivity to

parameter variations and also this method reduces the dynamical properties of a servo system.

A more promising method is to use acceleration compensation to suppress load vibration. Tn this

method the motor is controlled by a simple PT -controller and load acceleration can be measured or

estimated and used as a compensation feedback. Kang et al. (2000) and Lee et al. (1999) have used

this kind of a method successfully in the vibration control of elevators. The weakness of using

acceleration feedback is that the signal is usually very noisy. If the system is observable, it is possible

to estimate the state variables that are not directly accessible to measurement using the measurement

data from the state variables that are accessible. By using these state-variable estimates rather than

their measured values one can usually achieve an acceptable performance. State-variable estimates

may in some circumstances even be preferable to direct measurements, because the errors of the

instruments that provide these measurements may be larger than the errors in estimating these

variables.

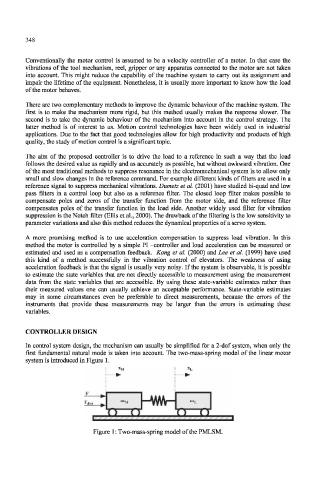

CONTROLLER DESIGN

Tn control system design, the mechanism can usually be simplified for a 2-dof system, when only the

first fundamental natural mode is taken into account. The two-mass-spring model of the linear motor

system is introduced in Figure 1.

\-m-

m M

Figure 1: Two-mass-spring model of the PMLSM.