Page 90 - Mechatronics for Safety, Security and Dependability in a New Era

P. 90

Ch16-I044963.fm Page 74 Tuesday, August 1, 2006 9:08 PM

Ch16-I044963.fm

74 74 Page 74 Tuesday, August 1, 2006 9:08 PM

Lower leg

Lower leg

Flexible wire

• —

Hard belt

Smooth paper

Smooth paper

Coil spring

Ball chain

Strain gauge

Flat spring

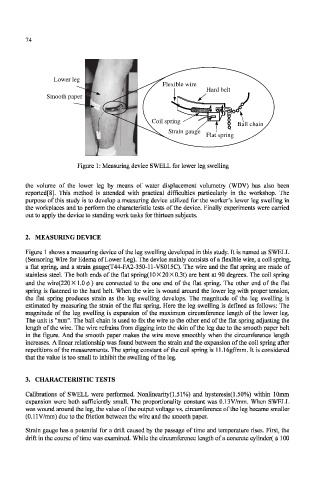

Figure 1: Measuring device SWELL for lower leg swelling

the volume of the lower leg by means of water displacement volumetry (WDV) has also been

reported[8]. This method is attended with practical difficulties particularly in the workshop. The

purpose of this study is to develop a measuring device utilized for the worker's lower leg swelling in

the workplaces and to perform the characteristic tests of the device. Finally experiments were carried

out to apply the device to standing work tasks for thirteen subjects.

2. MEASURING DEVICE

Figure 1 shows a measuring device of the leg swelling developed in this study. It is named as SWELL

(Sensoring Wire for Edema of Lower Leg). The device mainly consists of a flexible wire, a coil spring,

a flat spring, and a strain gauge(T44-FA2-350-ll-VS015C). The wire and the flat spring are made of

stainless steel. The both ends of the flat spring(10X20X0.3t) are bent at 90 degrees. The coil spring

and the wire(220X 1.00) are connected to the one end of the flat spring. The other end of the flat

spring is fastened to the hard belt. When the wire is wound around the lower leg with proper tension,

the flat spring produces strain as the leg swelling develops. The magnitude of the leg swelling is

estimated by measuring the strain of the flat spring. Here the leg swelling is defined as follows: The

magnitude of the leg swelling is expansion of the maximum circumference length of the lower leg.

The unit is "mm". The ball chain is used to fix the wire to the other end of the flat spring adjusting the

length of the wire. The wire refrains from digging into the skin of the leg due to the smooth paper belt

in the figure. And the smooth paper makes the wire move smoothly when the circumference length

increases. A linear relationship was found between the strain and the expansion of the coil spring after

repetitions of the measurements. The spring constant of the coil spring is 11.16gf/mm. It is considered

that the value is too small to inhibit the swelling of the leg.

3. CHARACTERISTIC TESTS

Calibrations of SWELL were performed. Nonlinearity(1.51%) and hysteresis(1.50%) within 10mm

expansion were both sufficiently small. The proportionality constant was 0.13V/mm. When SWELL

was wound around the leg, the value of the output voltage vs. circumference of the leg became smaller

(0.11 V/mm) due to the friction between the wire and the smooth paper.

Strain gauge has a potential for a drift caused by the passage of time and temperature rises. First, the

drift in the course of time was examined. While the circumference length of a concrete cylinder( 0 100