Page 105 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 105

Industrial waters 85

20,000 1 I

J

5

’ 15,000

B 10,000 ,

b

e,

5,000

0

0

Jun-Ol Aug-01 Oct-01 Dec-01

Date

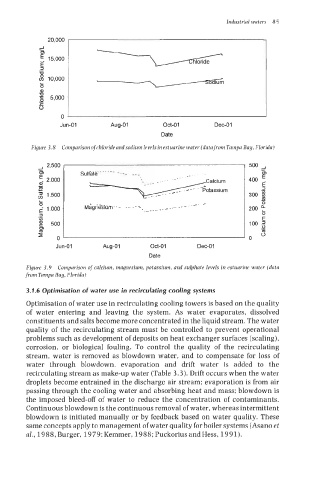

Figure 3.8 Comparison of chloride andsodium levelsin estuarine water (data from Tampa Bay, Florida)

2,500

~ 500 4

a Sulfate ””-- ---. ... P

E 2,000 400 ”

ai

P 5 ._

1,500 300 g

b - 3 ---’ - I

0

M&g;&um..- .-.--\ _*__.- 200

.,____--

.- 5- l,ooo - 0

u) E

g 500 100 .;

CJ) -

m

0

0- 0

3.7.6 Optimisation of water use in recirculating cooling systems

Optimisation of water use in recirculating cooling towers is based on the quality

of water entering and leaving the system. As water evaporates, dissolved

constituents and salts become more concentrated in the liquid stream. The water

quality of the recirculating stream must be controlled to prevent operational

problems such as development of deposits on heat exchanger surfaces (scaling),

corrosion, or biological fouling. To control the quality of the recirculating

stream, water is removed as blowdown water, and to compensate for loss of

water through blowdown, evaporation and drift water is added to the

recirculating stream as make-up water (Table 3.3). Drift occurs when the water

droplets become entrained in the discharge air stream: evaporation is from air

passing through the cooling water and absorbing heat and mass: blowdown is

the imposed bleed-off of water to reduce the concentration of contaminants.

Continuous blowdown is the continuous removal of water, whereas intermittent

blowdown is initiated manually or by feedback based on water quality. These

same concepts apply to management of water quality for boiler systems (Asano et

al., 1988, Burger, 1979: Kemmer, 1988: Puckorius andHess, 1991).