Page 265 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 265

2 34 i\.lerribranes for Iridiistrinl Wnstewater Recovery arid Re-use

MF

v v -

mn

ank

To stabon

distribution main

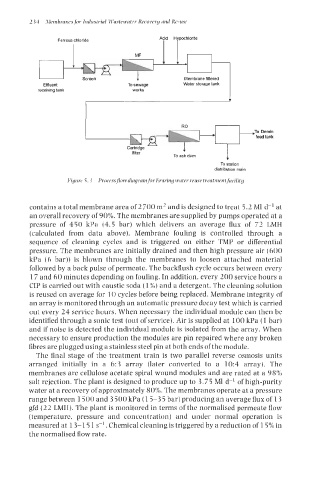

Figiirc 5.3 1’ror.ess~owdiagrani for Eraririg water reiise treatrnerit facihty

contains a total membrane area of 2 700 m2 and is designed to treat 5.2 M1 d-l at

an overall recovery of 90%. The membranes are supplied by pumps operated at a

pressure of 450 kPa (4.5 bar) which delivers an average flux of 72 LMH

(calculated from data above). Membrane fouling is controlled through a

sequence of cleaning cycles and is triggered on either TMP or differential

pressure. The membranes are initially drained and then high pressure air (600

kPa (6 bar)) is blown through the membranes to loosen attached material

followed by a back pulse of permeate. The backflush cycle occurs between every

17 and 60 minutes depending on fouling. In addition, every 200 service hours a

CIP is carried out with caustic soda (1%) and a detergent. The cleaning solution

is reused on average for 10 cycles before being replaced. Membrane integrity of

an array is monitored through an automatic pressure decay test which is carried

out every 24 service hours. When necessary the individual module can then be

identified through a sonic test (out of service). Air is supplied at 100 kPa (1 bar)

and if noise is detected the individual module is isolated from the array. When

necessary to ensure production the modules are pin repaired where any broken

fibres are plugged using a stainless steel pin at both ends of the module.

The final stage of the treatment train is two parallel reverse osmosis units

arranged initially in a 6:3 array (later converted to a 10:4 array). The

membranes are cellulose acetate spiral wound modules and are rated at a 98%

salt rejection. The plant is designed to produce up to 3.75 M1 d-l of high-purity

water at a recovery of approximately 80%. The membranes operate at a pressure

range between 1500 and 3 500 kPa (1 5-3 5 bar) producing an average flux of 13

gfd (22 LMH). The plant is monitored in terms of the normalised permeate flow

(temperature, pressure and concentration) and under normal operation is

measured at 13-1 5 1 s-I. Chemical cleaning is triggered by a reduction of 15% in

the normalised flow rate.