Page 30 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 30

10 Membranes for Industrial Wastewater Recovery and Re-use

10000

9 1000

a

.- 6

0

m

Q

3 100

aI

>

.-

m -

c.

3

f

0 10

1

1991 1992 1993 1994 1995 1996 1997 1998 1999

Year

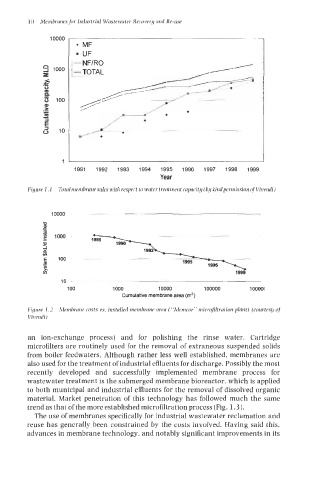

Figure 1.1 Total membrane sales with respect to water treatment capacity (by kindpermission of Vivendi)

10000 - ~

10 4

I00 1000 10000 100000 1 OOOO(

Cumulative membrane area (m2)

Figure I .2 Membrane costs 11s. installed membrane area (“Memcor” microfiltration plant) (courtesy of

Vivendi)

an ion-exchange process) and for polishing the rinse water. Cartridge

microfilters are routinely used for the removal of extraneous suspended solids

from boiler feedwaters. Although rather less well established, membranes are

also used for the treatment of industrial effluents for discharge. Possibly the most

recently developed and successfully implemented membrane process for

wastewater treatment is the submerged membrane bioreactor, which is applied

to both municipal and industrial effluents for the removal of dissolved organic

material. Market penetration of this technology has followed much the same

trend as that of the more established microfiltration process (Fig. 1.3).

The use of membranes specifically for industrial wastewater reclamation and

reuse has generally been constrained by the costs involved. Having said this,

advances in membrane technology, and notably significant improvements in its