Page 47 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 47

Membrane technology 2 7

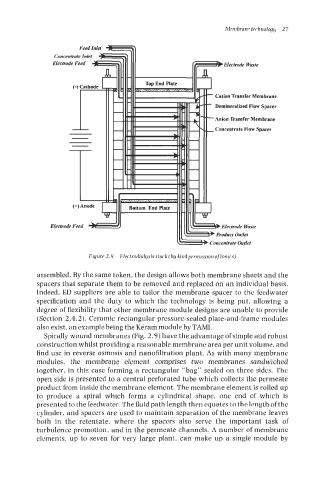

Conrentrote Inlet

Electrode Feed Electrode Waste

Cation Transfer Membrane

Demineralized Flow Spacer

Anion Transfer Membrane

Concentrate Flow Spacer

-

Electrode Feed Electrode Waste

Concentrate Outlet

Figure 2.8 Elrrtrodialysisstack (by kindpermission oflonics)

assembled. By the same token, the design allows both membrane sheets and the

spacers that separate them to be removed and replaced on an individual basis.

Indeed, ED suppliers are able to tailor the membrane spacer to the feedwater

specification and the duty to which the technology is being put, allowing a

degree of flexibility that other membrane module designs are unable to provide

(Scction 2.4.2). Ceramic rectangular pressure-sealed plate-and-frame modules

also exist, an example being the Keram module by TAMI.

Spirally wound membranes (Fig. 2.9) have the advantage of simple and robust

construction whilst providing a reasonable membrane area per unit volume, and

find use in reverse osmosis and nanofiltration plant. As with many membrane

modules, the membrane element comprises two membranes sandwiched

together, in this case forming a rectangular “bag” sealed on three sides. The

open side is presented to a central perforated tube which collects the permeate

product from inside the membrane element. The membrane element is rolled up

to produce a spiral which forms a cylindrical shape, one end of which is

presented to the feedwater. The fluid path length then equates to the length of the

cylinder, and spacers are used to maintain separation of the membrane leaves

both in the retentate, where the spacers also serve the important task of

turbulence promotion, and in the permeate channels. A number of membrane

elements, up to seven for very large plant, can make up a single module by