Page 51 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 51

Membrane technology 3 1

pumped liquid flow. Such has been the success of the application of coarse

aeration to submerged MBR systems in municipal and industrial effluent

treatment that submerged aerated systems are now starting to be applied to

largely abiotic pure water systems.

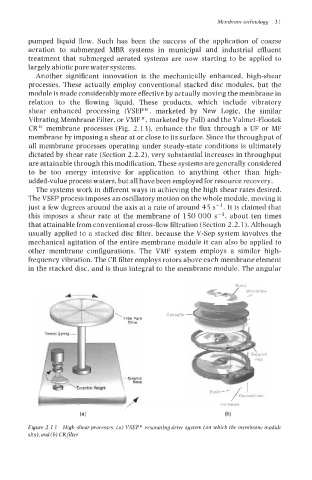

Another significant innovation is the mechanically enhanced, high-shear

processes. These actually employ conventional stacked disc modules, but the

module is made considerably more effective by actually moving the membrane in

relation to the flowing liquid. These products, which include vibratory

shear enhanced processing (VSEP“, marketed by New Logic, the similar

Vibrating Membrane Filter, or VMF@, marketed by Pall) and the Valmet-Flootek

CRfX’ membrane processes (Fig. 2.13), enhance the flux through a UF or MF

membrane by imposing a shear at or close to its surface. Since the throughput of

all membrane processes operating under steady-state conditions is ultimately

dictated by shear rate (Section 2.2.2), very substantial increases in throughput

are attainable through this modification. These systems are generally considered

to be too energy intensive for application to anything other than high-

added-value process waters, but all have been employed for resource recovery.

The systems work in different ways in achieving the high shear rates desired.

The VSEP process imposes an oscillatory motion on the whole module, moving it

just a few degrees around the axis at a rate of around 45 s-l. It is claimed that

this imposes a shear rate at the membrane of 150 000 s-l, about ten times

that attainable from conventional cross-flow filtration (Section 2.2.1). Although

usually applied to a stacked disc filter, because the V-Sep system involves the

mechanical agitation of the entire membrane module it can also be applied to

other membrane configurations. The VMF system employs a similar high-

frequency vibration. The CR filter employs rotors above each membrane element

in the stacked disc, and is thus integral to the membrane module. The angular

6“ *.a-

Figure 2.13 High-shear processes: (a) VSEP” resonating drive system (on which the membrane module

sits), and (b) CRfiZter