Page 337 - A Practical Guide from Design Planning to Manufacturing

P. 337

Microprocessor Packaging 307

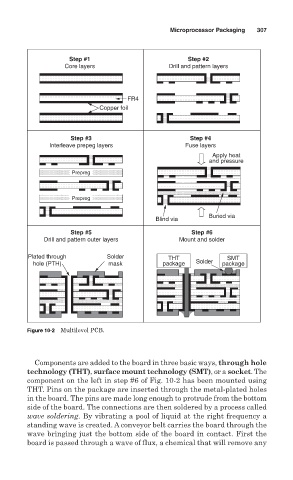

Step #1 Step #2

Core layers Drill and pattern layers

FR4

Copper foil

Step #3 Step #4

Interleave prepeg layers Fuse layers

Apply heat

and pressure

Prepreg

Prepreg

Buried via

Blind via

Step #5 Step #6

Drill and pattern outer layers Mount and solder

Plated through Solder THT SMT

hole (PTH) mask package Solder package

Figure 10-2 Multilevel PCB.

Components are added to the board in three basic ways, through hole

technology (THT), surface mount technology (SMT), or a socket. The

component on the left in step #6 of Fig. 10-2 has been mounted using

THT. Pins on the package are inserted through the metal-plated holes

in the board. The pins are made long enough to protrude from the bottom

side of the board. The connections are then soldered by a process called

wave soldering. By vibrating a pool of liquid at the right frequency a

standing wave is created. A conveyor belt carries the board through the

wave bringing just the bottom side of the board in contact. First the

board is passed through a wave of flux, a chemical that will remove any