Page 24 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 24

INTRODUCTION

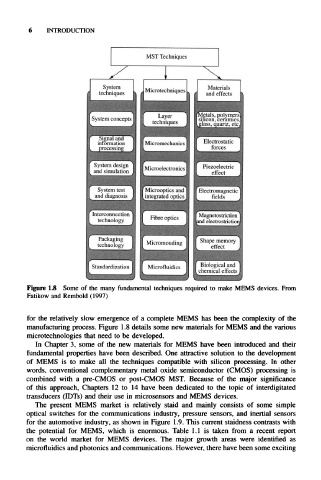

Figure 1.8 Some of the many fundamental techniques required to make MEMS devices. From

Fatikow and Rembold (1997)

for the relatively slow emergence of a complete MEMS has been the complexity of the

manufacturing process. Figure 1.8 details some new materials for MEMS and the various

microtechnologies that need to be developed.

In Chapter 3, some of the new materials for MEMS have been introduced and their

fundamental properties have been described. One attractive solution to the development

of MEMS is to make all the techniques compatible with silicon processing. In other

words, conventional complementary metal oxide semiconductor (CMOS) processing is

combined with a pre-CMOS or post-CMOS MST. Because of the major significance

of this approach, Chapters 12 to 14 have been dedicated to the topic of interdigitated

transducers (IDTs) and their use in microsensors and MEMS devices.

The present MEMS market is relatively staid and mainly consists of some simple

optical switches for the communications industry, pressure sensors, and inertia! sensors

for the automotive industry, as shown in Figure 1.9. This current staidness contrasts with

the potential for MEMS, which is enormous. Table 1.1 is taken from a recent report

on the world market for MEMS devices. The major growth areas were identified as

microfluidics and photonics and communications. However, there have been some exciting