Page 259 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 259

THERMAL SENSORS 239

8.2.4 SAW Temperature Sensor

In certain circumstances, it may be cost-effective to use other technologies. For example,

the remote wireless sensing of temperature - perhaps on a rotating part - requires a

temperature IC, radio frequency (RF) transmitter, and a battery power supply. An alter-

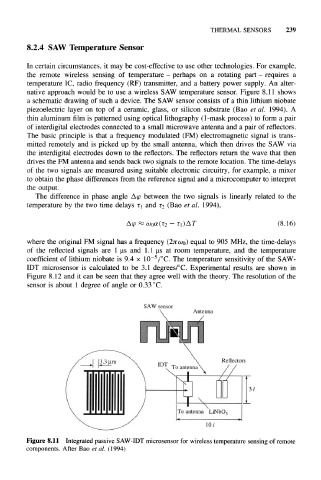

native approach would be to use a wireless SAW temperature sensor. Figure 8.11 shows

a schematic drawing of such a device. The SAW sensor consists of a thin lithium niobate

piezoelectric layer on top of a ceramic, glass, or silicon substrate (Bao et al. 1994). A

thin aluminum film is patterned using optical lithography (1-mask process) to form a pair

of interdigital electrodes connected to a small microwave antenna and a pair of reflectors.

The basic principle is that a frequency modulated (FM) electromagnetic signal is trans-

mitted remotely and is picked up by the small antenna, which then drives the SAW via

the interdigital electrodes down to the reflectors. The reflectors return the wave that then

drives the FM antenna and sends back two signals to the remote location. The time-delays

of the two signals are measured using suitable electronic circuitry, for example, a mixer

to obtain the phase differences from the reference signal and a microcomputer to interpret

the output.

The difference in phase angle A<p between the two signals is linearly related to the

temperature by the two time delays T\ and 12 (Bao et al. 1994),

(8.16)

where the original FM signal has a frequency (ITCCDQ] equal to 905 MHz, the time-delays

of the reflected signals are 1 us and 1.1 us at room temperature, and the temperature

-5

coefficient of lithium niobate is 9.4 x 10 /°C. The temperature sensitivity of the SAW-

IDT microsensor is calculated to be 3.1 degrees/°C. Experimental results are shown in

Figure 8.12 and it can be seen that they agree well with the theory. The resolution of the

sensor is about 1 degree of angle or 0.33 °C.

SAW sensor

Antenna

10/

Figure 8.11 Integrated passive SAW-IDT microsensor for wireless temperature sensing of remote

components. After Bao et al. (1994)