Page 279 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 279

MECHANICAL SENSORS 259

capacitors and the output voltage is related to the deflection of the membrane A* and

hence the applied pressure (P — P 0).

V out a AC a AJC a (P - P 0) (8.33)

In this case, the accurate positioning of the pickup electrodes is crucial.

By controlling the background pressure P 0, it is possible to fabricate the following

basic types of pressure sensors:

• An absolute pressure sensor that is referenced to a vacuum (P 0 = 0)

• A gauge-type pressure sensor that is referenced to atmospheric pressure (P 0 = 1 atm)

• A differential or relative type (P 0 is constant).

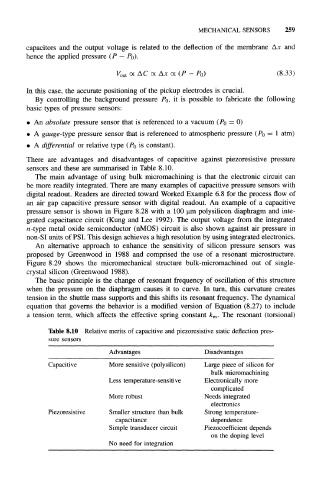

There are advantages and disadvantages of capacitive against piezoresistive pressure

sensors and these are summarised in Table 8.10.

The main advantage of using bulk micromachining is that the electronic circuit can

be more readily integrated. There are many examples of capacitive pressure sensors with

digital readout. Readers are directed toward Worked Example 6.8 for the process flow of

an air gap capacitive pressure sensor with digital readout. An example of a capacitive

pressure sensor is shown in Figure 8.28 with a 100 urn polysilicon diaphragm and inte-

grated capacitance circuit (Kung and Lee 1992). The output voltage from the integrated

n-type metal oxide semiconductor (nMOS) circuit is also shown against air pressure in

non-Si units of PSI. This design achieves a high resolution by using integrated electronics.

An alternative approach to enhance the sensitivity of silicon pressure sensors was

proposed by Greenwood in 1988 and comprised the use of a resonant microstructure.

Figure 8.29 shows the micromechanical structure bulk-micromachined out of single-

crystal silicon (Greenwood 1988).

The basic principle is the change of resonant frequency of oscillation of this structure

when the pressure on the diaphragm causes it to curve. In turn, this curvature creates

tension in the shuttle mass supports and this shifts its resonant frequency. The dynamical

equation that governs the behavior is a modified version of Equation (8.27) to include

a tension term, which affects the effective spring constant k m. The resonant (torsional)

Table 8.10 Relative merits of capacitive and piezoresistive static deflection pres-

sure sensors

Advantages Disadvantages

Capacitive More sensitive (polysilicon) Large piece of silicon for

bulk micromachining

Less temperature-sensitive Electronically more

complicated

More robust Needs integrated

electronics

Piezoresistive Smaller structure than bulk Strong temperature-

capacitance dependence

Simple transducer circuit Piezocoefficient depends

on the doping level

No need for integration