Page 278 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 278

258 MICROSENSORS

Piezoresistors Glass cap

Polysilicon

diaphragm

OvXXXXXXXXXXXXXXXI

Anodic bonding

(a) Glass support

L Inlet hole

Reference Sensing

capacitors capacitors

Pressure

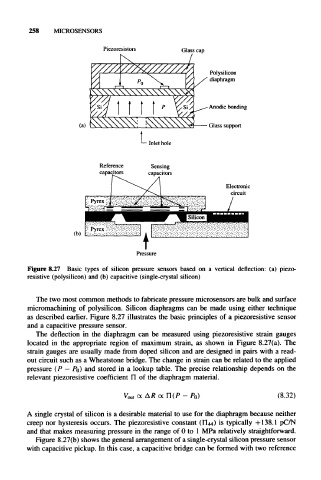

Figure 8.27 Basic types of silicon pressure sensors based on a vertical deflection: (a) piezo-

resistive (polysilicon) and (b) capacitive (single-crystal silicon)

The two most common methods to fabricate pressure microsensors are bulk and surface

micromachining of polysilicon. Silicon diaphragms can be made using either technique

as described earlier. Figure 8.27 illustrates the basic principles of a piezoresistive sensor

and a capacitive pressure sensor.

The deflection in the diaphragm can be measured using piezoresistive strain gauges

located in the appropriate region of maximum strain, as shown in Figure 8.27(a). The

strain gauges are usually made from doped silicon and are designed in pairs with a read-

out circuit such as a Wheatstone bridge. The change in strain can be related to the applied

pressure (P — P 0) and stored in a lookup table. The precise relationship depends on the

relevant piezoresistive coefficient n of the diaphragm material.

A

V out oc /?ocn(/>-/> 0 ) (8.32)

A single crystal of silicon is a desirable material to use for the diaphragm because neither

creep nor hysteresis occurs. The piezoresistive constant (044) is typically +1–138.1 pC/N

and that makes measuring pressure in the range of 0 to 1 MPa relatively straightforward.

Figure 8.27(b) shows the general arrangement of a single-crystal silicon pressure sensor

with capacitive pickup. In this case, a capacitive bridge can be formed with two reference