Page 290 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 290

270 MICROSENSORS

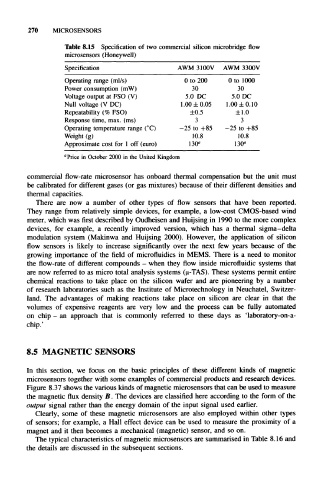

Table 8.15 Specification of two commercial silicon microbridge flow

microsensors (Honeywell)

Specification AWM 3100V AWM 3300V

Operating range (ml/s) 0 to 200 0 to 1000

Power consumption (mW) 30 30

Voltage output at FSO (V) 5.0 DC 5.0 DC

Null voltage (V DC) 1.00 ±0.05 1.00±0.10

Repeatability (% FSO) ±0.5 ±1.0

Response time, max. (ms) 3 3

Operating temperature range (°C) -25 to +85 -25 to +85

Weight (g) 10.8 10.8

Approximate cost for 1 off (euro) 130 a 130 a

a

Price in October 2000 in the United Kingdom

commercial flow-rate microsensor has onboard thermal compensation but the unit must

be calibrated for different gases (or gas mixtures) because of their different densities and

thermal capacities.

There are now a number of other types of flow sensors that have been reported.

They range from relatively simple devices, for example, a low-cost CMOS-based wind

meter, which was first described by Oudheisen and Huijsing in 1990 to the more complex

devices, for example, a recently improved version, which has a thermal sigma-delta

modulation system (Makinwa and Huijsing 2000). However, the application of silicon

flow sensors is likely to increase significantly over the next few years because of the

growing importance of the field of microfluidics in MEMS. There is a need to monitor

the flow-rate of different compounds - when they flow inside microfluidic systems that

are now referred to as micro total analysis systems (u-TAS). These systems permit entire

chemical reactions to take place on the silicon wafer and are pioneering by a number

of research laboratories such as the Institute of Microtechnology in Neuchatel, Switzer-

land. The advantages of making reactions take place on silicon are clear in that the

volumes of expensive reagents are very low and the process can be fully automated

on chip - an approach that is commonly referred to these days as 'laboratory-on-a-

chip.'

8.5 MAGNETIC SENSORS

In this section, we focus on the basic principles of these different kinds of magnetic

microsensors together with some examples of commercial products and research devices.

Figure 8.37 shows the various kinds of magnetic microsensors that can be used to measure

the magnetic flux density B. The devices are classified here according to the form of the

output signal rather than the energy domain of the input signal used earlier.

Clearly, some of these magnetic microsensors are also employed within other types

of sensors; for example, a Hall effect device can be used to measure the proximity of a

magnet and it then becomes a mechanical (magnetic) sensor, and so on.

The typical characteristics of magnetic microsensors are summarised in Table 8.16 and

the details are discussed in the subsequent sections.