Page 50 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 50

32 ELECTRONIC MATERIALS AND PROCESSING

Schematic of a medium-current

ion implanter

Resolving

Acceleration v- scan

High-voltage aperture

tube , p lates P lates Beam

terminal v. Wafer

mask

(target)

Analyzer

magnet

Faraday cup

Ion source

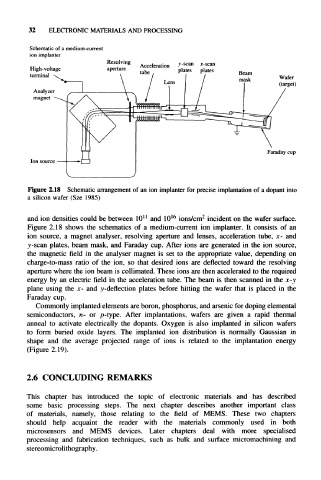

Figure 2.18 Schematic arrangement of an ion implanter for precise implantation of a dopant into

a silicon wafer (Sze 1985)

11

and ion densities could be between 10 and 10 16 ions/cm 2 incident on the wafer surface.

Figure 2.18 shows the schematics of a medium-current ion implanter. It consists of an

ion source, a magnet analyser, resolving aperture and lenses, acceleration tube, x- and

y-scan plates, beam mask, and Faraday cup. After ions are generated in the ion source,

the magnetic field in the analyser magnet is set to the appropriate value, depending on

charge-to-mass ratio of the ion, so that desired ions are deflected toward the resolving

aperture where the ion beam is collimated. These ions are then accelerated to the required

energy by an electric field in the acceleration tube. The beam is then scanned in the x-y

plane using the x- and y-deflection plates before hitting the wafer that is placed in the

Faraday cup.

Commonly implanted elements are boron, phosphorus, and arsenic for doping elemental

semiconductors, n- or p-type. After implantations, wafers are given a rapid thermal

anneal to activate electrically the dopants. Oxygen is also implanted in silicon wafers

to form buried oxide layers. The implanted ion distribution is normally Gaussian in

shape and the average projected range of ions is related to the implantation energy

(Figure 2.19).

2.6 CONCLUDING REMARKS

This chapter has introduced the topic of electronic materials and has described

some basic processing steps. The next chapter describes another important class

of materials, namely, those relating to the field of MEMS. These two chapters

should help acquaint the reader with the materials commonly used in both

microsensors and MEMS devices. Later chapters deal with more specialised

processing and fabrication techniques, such as bulk and surface micromachining and

stereomicrolithography.