Page 40 - Modern Control Systems

P. 40

Chapter 1 Introduction to Control Systems

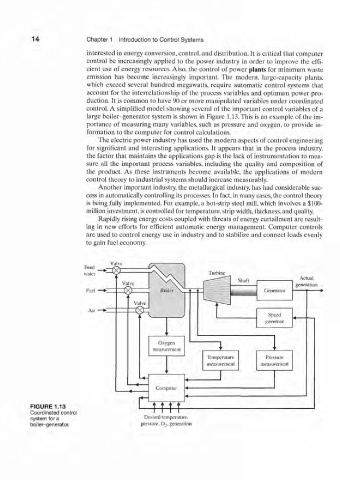

interested in energy conversion, control, and distribution. It is critical that computer

control be increasingly applied to the power industry in order to improve the effi-

cient use of energy resources. Also, the control of power plants for minimum waste

emission has become increasingly important. The modern, large-capacity plants,

which exceed several hundred megawatts, require automatic control systems that

account for the interrelationship of the process variables and optimum power pro-

duction. It is common to have 90 or more manipulated variables under coordinated

control. A simplified model showing several of the important control variables of a

large boiler-generator system is shown in Figure 1.13. This is an example of the im-

portance of measuring many variables, such as pressure and oxygen, to provide in-

formation to the computer for control calculations.

The electric power industry has used the modern aspects of control engineering

for significant and interesting applications. It appears that in the process industry,

the factor that maintains the applications gap is the lack of instrumentation to mea-

sure all the important process variables, including the quality and composition of

the product. As these instruments become available, the applications of modern

control theory to industrial systems should increase measurably.

Another important industry, the metallurgical industry, has had considerable suc-

cess in automatically controlling its processes. In fact, in many cases, the control theory

is being fully implemented. For example, a hot-strip steel mill, which involves a $100-

million investment, is controlled for temperature, strip width, thickness, and quality.

Rapidly rising energy costs coupled with threats of energy curtailment are result-

ing in new efforts for efficient automatic energy management. Computer controls

are used to control energy use in industry and to stabilize and connect loads evenly

to gain fuel economy.

Valve

Feed , ^ - / Q v

Feed

Turbine

water v*^

Shaft Actual

Valve generation

Fuel Boiler Generator

Valve

<K Speed

Air

governor

Oxygen

measurement

Temperature Pressure

measurement measurement

Computer

FIGURE 1.13 WW

Coordinated control

system for a Desired temperature,

boiler-generator. pressure, O,, generation