Page 141 - Modular design for machine tools

P. 141

Engineering Guides and Future Perspectives of Modular Design 101

1. The repeatability of pallet positioning accuracy is better than 2 m.

2. The thermal elongation of the main spindle is 10 m after running

7 h at 1500 rpm rotational speed.

3. The Y axis quill for pallet fixing and traveling is preadjusted and

assembled in consideration of the applied loads in operation.

On the basis of the good reputation of the MA type, Tsugami once

developed a prototype of TC-based system machine, i.e., type TA3 shown

in Fig. 2-23, which can be characterized by its chucking mechanism

and automatic chuck changing; however, it was not on the market.

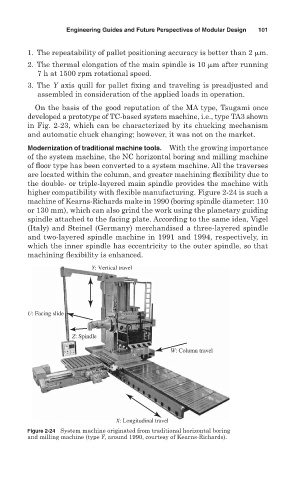

Modernization of traditional machine tools. With the growing importance

of the system machine, the NC horizontal boring and milling machine

of floor type has been converted to a system machine. All the traverses

are located within the column, and greater machining flexibility due to

the double- or triple-layered main spindle provides the machine with

higher compatibility with flexible manufacturing. Figure 2-24 is such a

machine of Kearns-Richards make in 1990 (boring spindle diameter: 110

or 130 mm), which can also grind the work using the planetary guiding

spindle attached to the facing plate. According to the same idea, Vigel

(Italy) and Steinel (Germany) merchandised a three-layered spindle

and two-layered spindle machine in 1991 and 1994, respectively, in

which the inner spindle has eccentricity to the outer spindle, so that

machining flexibility is enhanced.

Y: Vertical travel

U: Facing slide

Z: Spindle

W: Column travel

X: Longitudinal travel

Figure 2-24 System machine originated from traditional horizontal boring

and milling machine (type F, around 1990, courtesy of Kearns-Richards).