Page 142 - Modular design for machine tools

P. 142

102 Modular Design Guide and Machine Tools Description

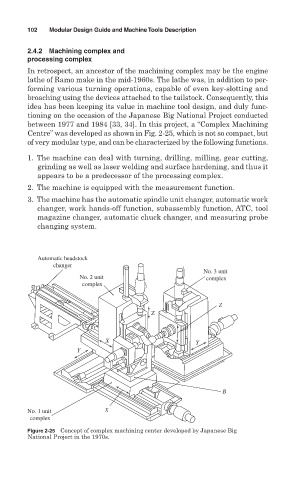

2.4.2 Machining complex and

processing complex

In retrospect, an ancestor of the machining complex may be the engine

lathe of Ramo make in the mid-1960s. The lathe was, in addition to per-

forming various turning operations, capable of even key-slotting and

broaching using the devices attached to the tailstock. Consequently, this

idea has been keeping its value in machine tool design, and duly func-

tioning on the occasion of the Japanese Big National Project conducted

between 1977 and 1984 [33, 34]. In this project, a “Complex Machining

Centre” was developed as shown in Fig. 2-25, which is not so compact, but

of very modular type, and can be characterized by the following functions.

1. The machine can deal with turning, drilling, milling, gear cutting,

grinding as well as laser welding and surface hardening, and thus it

appears to be a predecessor of the processing complex.

2. The machine is equipped with the measurement function.

3. The machine has the automatic spindle unit changer, automatic work

changer, work hands-off function, subassembly function, ATC, tool

magazine changer, automatic chuck changer, and measuring probe

changing system.

Automatic headstock

changer

No. 3 unit

No. 2 unit complex

complex

Z

Z

X Y

Y

B

No. 1 unit X

complex

Figure 2-25 Concept of complex machining center developed by Japanese Big

National Project in the 1970s.