Page 146 - Modular design for machine tools

P. 146

106 Modular Design Guide and Machine Tools Description

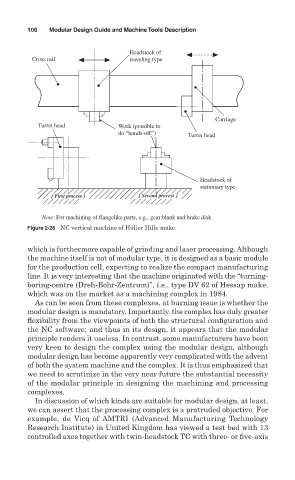

Headstock of

Cross rail traveling type

Carriage

Turret head Work (possible to

do “hands-off”)

Turret head

Headstock of

stationary type

[ First process ] [ Second process ]

Note: For machining of flangelike parts, e.g., gear blank and brake disk.

Figure 2-28 NC vertical machine of Hüller Hille make.

which is furthermore capable of grinding and laser processing. Although

the machine itself is not of modular type, it is designed as a basic module

for the production cell, expecting to realize the compact manufacturing

line. It is very interesting that the machine originated with the “turning-

boring-centre (Dreh-Bohr- Zentrum)”, i.e., type DV 62 of Hessap make,

which was on the market as a machining complex in 1984.

As can be seen from these complexes, at burning issue is whether the

modular design is mandatory. Importantly, the complex has duly greater

flexibility from the viewpoints of both the structural configuration and

the NC software; and thus in its design, it appears that the modular

principle renders it useless. In contrast, some manufacturers have been

very keen to design the complex using the modular design, although

modular design has become apparently very complicated with the advent

of both the system machine and the complex. It is thus emphasized that

we need to scrutinize in the very near future the substantial necessity

of the modular principle in designing the machining and processing

complexes.

In discussion of which kinds are suitable for modular design, at least,

we can assert that the processing complex is a protruded objective. For

example, de Vicq of AMTRI (Advanced Manufacturing Technology

Research Institute) in United Kingdom has viewed a test bed with 13

controlled axes together with twin-headstock TC with three- or five-axis